Livestock Mortality Composting For Large and Small Operations in the Sem-Arid West

Last Updated: 07/09by Thomas Bass, David Colburn, Jessica Davis, John Deering, Michael Fisher, Robert Flynn, Sara Lupis, Jay Norton, and Nicolette Schauermann

Why Compost Animal Mortalities?

Many livestock producers are concerned about proper mortality disposal and management. Proper management of animal mortalities on the farm/ranch/feedlot has important implications for nutrient management, herd and flock health, as well as farm/ranch family and public health. The purpose of proper mortality disposal is to prevent the spread of infectious, contagious and communicable diseases and to protect air, water and soil quality. Also, there are legal issues and requirements related to nutrient management and the permitting of animal feeding operations. To best ensure human health and safety, reduce regulatory risks, and protect environmental resources, livestock producers should become familiar with best management practices (BMPs) for dealing with dead animals. They should also be aware of state laws related to proper disposal or processing of mortalities.

Disposal of routine operational mortalities and catastrophic mortalities must be defined in a comprehensive nutrient management plan, used by most permitted animal feeding operations. In addition, zoos and other facilities that house large animals (or many animals) may benefit from the techniques and resources provided in this manual.

Mortality composting is an increasingly popular and viable alternative compared to other disposal practices because of cost savings, reduced environmental risks, and the generation of a useful end-product. This manual is designed to provide livestock producers in Montana, Wyoming, Colorado, New Mexico and surrounding states with the knowledge, tools, and resources to develop a mortality management plan, with specific focus on the composting option.

Unacceptable Animal Mortality Disposal

Abandonment

Though dragging off a carcass to the “boneyard” has been a historic practice, abandonment is strongly discouraged. Abandonment is likely illegal in most states. Examples of abandonment include: carcasses abandoned on the surface, in open pits, ditches, water features and sinkholes or in wells. Abandonment promotes extreme biological and disease hazard, threats to water quality, odors, flies, scavengers, rodents, and visual pollution.

Methods of Animal Mortality Disposal

Burning

Disposing of animal mortalities by open pyre burning is discouraged. Most producers have difficulty finding proper fuel to maintain temperature and flame, and struggle to obtain complete consumption of the carcass or carcasses in a timely manner. Air emissions are uncontrolled and likely dangerous, depending on the fuel source. Burning should only be considered in emergency situations, and with proper advisement and permission from the appropriate regulatory agency.

Incineration

Incineration is a safe method of carcass management from a bio-security standpoint. Incineration is different from burning because when practiced correctly, the entire carcass is quickly and completely consumed by fire and heat. This practice must be done in an approved device with air quality and emissions controls. Incineration is primarily utilized for disposing of small carcasses (such as poultry). The cost of fuel may limit adoption of this practice because it can be an energy intensive process.

Burial

Burial is probably the most common method of dead animal disposal, although some states have outlawed it. Most states have regulatory burial guidelines outlining site location, distance from waterways, depth to groundwater, etc. If proper procedures are used, burial is safe; however, certain portions of carcasses can persist for years in an anaerobic (low oxygen) environment and there is no assurance of pathogen reduction. During construction projects on former poultry farms, old burial pits have been discovered that contain intact birds. Sites with a high water table and well drained soils do not allow proper depth or cover of burial without threatening ground water. Burial pits are considered mass graves and, if not managed properly, may pose additional risks through the spread of disease and other environmental contamination.

Land Filling

Disposing of carcasses at a licensed landfill is considered an acceptable method of burial. Land filling may be an option in some areas; however, the legality of this will be based on the classification of the facility, local regulations, and the policy of the individual site. Even if the landfill is classified to accept carcasses, management must also grant permission. It is a good idea to have a written agreement with the landfill service if you plan to regularly use this method of disposal. Drawbacks to landfill disposal may include additional handling of the mortality, transportation and tipping fees, and potential disease transmission.

Rendering

Rendering is a heat-driven process that takes place at a special facility in which waste animal tissue is separated and converted into value-added materials. Rendering is a relatively simple method of mortality management for the farmer/rancher, and it leaves no lasting legacy on the farm. However, there are very few rendering facilities across the U.S., and there are often fees associated with a rendering service. This is a recommended practice for those with access to a rendering service. The cost of rendering should be weighed against time management, input cost, and possible bio-security breaches when compared to other available methods. Local livestock or poultry producers and Extension staff may be the best resource for determining if this service exists in your area.

Livestock Mortality Composting

For many species, carcass composting (i.e., the biological process of converting organic matter into fine-particle humus-like material) is an environmentally preferable method for managing mortalities. When performed correctly, the end-product may be reused in future mortality composting, and under certain conditions, applied to animal feed crops and forest crops. Poultry composting is a common practice and much information is available that describes how to dispose of birds in this way.

Composting is practical for larger carcasses. Many operations, even in cold climates, successfully compost larger stock including sows, cattle and horses. Composting large carcasses can save labor and land. This practice allows a dedicated area to be used and reused for carcass management; it is done above ground, thereby reducing the number of labor-intensive burial pits created as well as minimizing the number of buried carcasses on the property.

Technical procedures on composting cattle carcasses are available and continue to be studied and refined; this appears to be a viable option which will be described further in this manual. Most composting requires storm water protection, and possibly roof-type covering. Additional management and monitoring is required to refine the process, maintain temperatures, attain proper decomposition and prevent scavengers. Nutrients and organic matter in finished carcass compost can benefit forest and crop land; however, nutrient management guidelines should be followed. This publication focuses on aerobic composting in piles or windrows on the soil surface. Other methods do exist and are also continue to be studied.

Composting Principles

Composting is the “managed, biological, oxidation process that converts heterogeneous organic matter into a more homogeneous, fine-particle humus-like material” (Field Guide to On-farm Composting, 1999). This definition includes many important principles that need to be considered when composting.

Managing a compost pile can be viewed as “farming microorganisms” to provide optimum conditions for the bacteria and fungi that do the real work of composting. The microorganisms need four things: carbon (C), nitrogen (N), water, and oxygen. Generally, the carbon and nitrogen need to be provided in balance, and we usually aim for a C:N ratio of about 30:1 at the beginning of the composting process. To achieve this, it is important to know the C:N ratios of your composting feedstocks (i.e., carbon materials such as straw, sawdust, animal bedding, etc.) and devise a good “recipe” or mixture. However, departure from this common wisdom for mortality composting will be discussed in this manual as C:N ratios exceed the recommendation (much greater carbon) when dealing with dead animals. Likewise, in the early stages of carcass composting mixing is not feasible.

As noted above, true composting must take place in the presence of air or “under aerobic conditions”. The bacteria and fungi that break down organic wastes in the pile require oxygen to achieve a compost end product. If oxygen is inadequate due to high moisture levels, waste will still degrade, but it will degrade by rotting or fermenting rather than composting. Odor may be excessive, in this case!

Water and oxygen must be provided for the microorganisms and are related to each other. If the compost is too wet, the oxygen levels will be too low. In most composting scenarios best success is attained with a moisture level at about 50%. The moisture content can be determined by weighing a sample, drying it and then reweighing, but it can also be estimated from a “squeeze test.” Just squeeze the compost mix in your hand. It should be wet enough to stay together in a ball, and you should only be able to squeeze a little trickle of water out in between your fingers. To achieve this moisture level, watering and shaping the pile to accept moisture is often necessary.

Composting Goats and Sheep:

Though composting of medium to large carcasses and land applying the material is proving to be feasible, careful consideration must be given for goats and sheep due to the prevalence of scrapie, a prion disease, in flocks across the U.S. This disease is a transmissible spongiform encephalopathy (TSE) similar to BSE (i.e., mad cow disease) and the human Creutzfeldt-Jakob disease. If compost from diseased animals were used as fertilizer, it would create a serious bio-security threat. Fate of compost from sheep and goats should be carefully considered. Be sure to seek expert advice prior to disposal of these species. If a producer has a certified scrapie free flock, then they could proceed with composting in relative safety.

The oxygen content in a compost pile should be about 5-20%. Some operators purchase hand-held oxygen meters to periodically measure that level. A drop in compost pile temperature after the start of the process is often a sign that there is an inadequate level of oxygen. Turning the pile is a management practice that is commonly used both to mix the ingredients and to add oxygen into the pile. The use of bulking material (a coarse-textured organic waste like wood chips) also aids in aeration of a compost pile. Turning should only be done after the active stage of composting. For poultry, you can turn after 2-3 weeks; large livestock generally require 3-6 months.

Incorporating Animals into the Composting Process

Influence of Animal Size

Size and volume of mortalities will directly influence the physical footprint of the pile or volume of bin space designed, amount of carbon material required, and the time required to fully compost the carcass(es). Smaller carcasses have more surface area relative to mass; this provides for more carbon material to carcass interaction. Similarly, cutting or breaking apart large carcasses can speed up the composting process. While properly constructed and layered poultry mortality compost will process in a matter of a few short weeks, cattle will take months (6-12) under average conditions (in static piles; i.e., no turning).

Bones remaining at 3 months, skull on left, spine on right. These will nearly breakdown completely when recovered for 3 more months, credit: Schauermann

Preparation and Placement

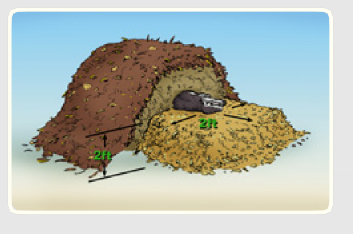

For larger livestock, the carcass should be laid on its side on the middle of the base material with the body cavity opened and the rumen punctured for cattle, sheep and goats. This is done to prevent bloating and bursting which will displace cover and result in additional odor and nuisance. The carcass should be covered completely with material on all sides (as described in the next section). The finished pile may reach up to six feet in height, in the example of a large cow. Small carcasses should be layered and arranged to maintain carbon margins around each dead animal. Small carcasses can also be stacked in tiers with carbon layers in between.

Cows on base, credit: Upper picture: TX A&M Agrilife Extension. Lower picture: Dafoe

Base and Cover

Considering that a large carcass is very high in moisture and nitrogen, adding too much carbon will not likely be a threat to composting success. In the case of mortality composting, proper pile construction will result in unbalanced C:N, considerably higher than the common 30:1 ratio. Moisture distribution will be uneven throughout the pile and there are likely to be pockets of anaerobic decomposition immediately around the mortality. While much of the external carbon does not interact with the carcass at the center, it serves a larger role in bio-filtration and insulation. The extra carbon material is also valuable in absorbing excess moisture from the mortality. Conventional turning and proper C:N balance comes into play at the end of this process, weeks after the mortality has been consumed by the process.

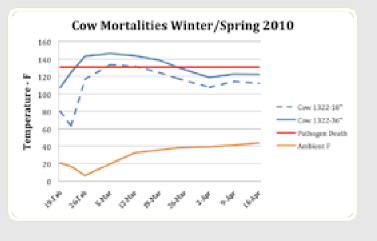

Winter tip — surrounding the carcasses in warm or active compost will give them a quicker start, especially for winter or early spring mortalities. In Montana, producers have been successful with attaining necessary temperatures by placing non-frozen carcasses in the pile and building the core with silage, warm compost or manure solids. The pile should always be capped with a “clean” material such as sawdust or chopped straw. Likewise, getting carcasses started in compost before they freeze in the field helps the pile attain and maintain desirable temperatures.

Successful composting of mortalities has been reported with base thicknesses between 12 to 24 inches. The base should be comprised of a material that is both absorbent and bulky, such as wood chips and shreds with sizable pieces being 4 to 6 inches in length. This base material is important for achieving satisfactory porosity for aeration. Material that packs tightly or is excessively wet is not recommended. The base material should not be excessively dry either, but moist like a damp, wrung-out sponge. To save time, always have a couple bases ready to accept animal mortalities. The carcass can be placed once a satisfactory base is established.

Core material can now be placed around the mortality. This is an opportunity to use a variety of materials found onsite or regionally. Tables 1 and 2 provide a list of materials that have been used in the Rocky Mountain region. The material added directly around the sides and top of the carcass does not need to be as porous as the base; also, if the carbon source has odor associated with it, the core around the carcasses is the ideal place for its use. Manure, silage, and other active materials, with a low C:N ratio may be ideal for this layer. Finally, the cap may also be a finer material than the base, and should be low in odor. Core and cap materials such as silage or moist sawdust in the 50-60% moisture range are ideal. The addition of the cap should bring the final margin around the carcass to a range of 18-24 inches, as the illustration shows.

Estimates of total material needed to fully compost a full grown cow are 12 cubic yards, or for 1,000 lbs of carcass, 7.4 cubic yards (200 ft3). The difference in the estimates can be attributed to the thicker base recommended by some experts. Practically speaking, for a mature cow, a proper base will be about 9 feet wide by 10 feet long. Once the mortality is placed in the middle of the base, cover to achieve at least a 24 inch margin in all directions. Considering side slope, material on top will likely be more than 24 inches above the mortality to achieve the proper margin. When layering smaller carcasses, or parts of carcasses, an 8 to 12 inch margin should be maintained around each carcass. Bins and bunkers can reduce the overall size and foot print of piles.

Cow position in pile, credit: Cornell Waste Management Institute

Layered small carcasses, credit: Cornell Waste Management Institute

Carbon Options

Table 1. Most Commonly used carbon material in the Rocky Mountain Corridor; sources, pros, and cons for each. Ideal pile construction will have coarse material base, with other materials in core around the carcass material and an inert material for a cap such as sawdust or compost.

|

Material |

Source(s) |

Pros |

Cons |

|

straw & hay (common) |

local farms, onsite, zoos |

availability |

compresses, pore space diminishes quickly; C:N 17:1 |

|

hay (alfalfa) |

Local farms, onsite, zoos |

availability |

compresses, pore space diminishes quickly;12:1 C:N |

|

wood chips |

timber mill, inert landfill, municipal yard waste, beetlekill |

good pore space, especially for base of pile; 300:1 |

may be expensive |

|

saw dust |

timber mill, wood based industry, beetlekill |

good cap material for odor control, green saw dust has good moisture for composting; 300:1 |

may be expensive |

|

compost |

onsite, compost distributors |

active material, best for core |

low pore space |

|

manure (various species) |

onsite |

active material, best for core |

odor, leaching potential, low pore space |

|

horse manure |

racetracks, boarding facilities |

45:1 C:N |

Low pore space, limited by region |

|

separated manure solids |

neighbors, onsite |

active material, best for core |

may still be too wet |

|

silage |

onsite |

active material, best for core; 40:1 C:N |

odor, leaching potential, low/ medium pore space |

|

grain residues/hulls |

local mills/granaries |

best for core |

low pore space, oil seed residues may lead to odors |

|

waste feed |

onsite, feed lanes, storage |

Active material |

Possible odors, variable composition |

|

cull potatoes |

Potato farms |

Best for core; could be mixed with dry material |

High moisture (~80%) |

|

biosolids |

City waste management companies, municipalities |

Good N source |

Possible heavy metals, pathogens |

|

yardwaste |

Homeowners, landscape companies, municipalities |

Can be good for base or cap |

Variable C/N ratio and irregular flow; 15:1 C:N; potential trash |

Table 2. Unique or locally utilized carbon materials of the Rocky Mountain corridor; sources, pros, and cons of each. Ideal pile construction will have coarse material base, with other materials in core around carcass(es) and an inert material for a cap such as sawdust or compost.

|

Material |

Source(s) |

Pros |

Cons |

|

Fruit wastes |

Orchards, vineyards, wineries |

For core; may need to be mixed w/ drier material |

Very wet (60-90% water) |

|

Chile skins |

Chile processors |

Bulking agent |

excess water directly from processor, nuisance factor |

|

Cotton gin waste |

Cotton gins |

Aerates well, holds moisture, good pore space |

Hauling costs, varies by region, 14:1 C:N |

|

Garment processing fibers |

garment processor |

46:1 C:N |

Wet product, hauling, very poor pore space |

|

Paper mill waste |

pulp and paper plants |

95:1 C:N |

Distance |

|

Pecan cleanings |

pecan processors |

Bulking agent |

Possible odor issues |

|

Pecan trimmings |

pecan farms |

Bulking agent |

Post processing |

Windrows, Wooden Bins, or Hay Bale Bins/Bunkers—Footprint and Sizing

As previously mentioned, the size of a compost pile can be reduced through the use of bins or bunkers. Windrows and piles, while providing the best passive air flow, will have the largest physical footprint and may pose the greatest attraction to scavengers if the area is not appropriately fenced. The use of some type of structure to contain the area and reduce physical footprint is recommended. This also provides visual screening. Permanent, slatted wooden or metal walls can also be constructed for large carcasses, though it represents a greater expense. Some engineers recommend roofs over mortality compost bins, even in arid climates. A producer can discuss this and other compost facility decisions with their county agent or local USDA- NRCS conservation professional. Large square or round hay bales can be used to construct temporary bins; bales placed around the pile’s perimeter help exclude pests and absorb any possible run-off. Bins for small ruminants, pigs or other stock, could be built with small square bales. Temporary fencing or stock panels can be used to bar the front of the mortality compost bin and exclude nuisance and scavenger animals. (Additional information and USDA-NRCS standards for this practice and related facilities can be found in Practice Standard 316 and the National Engineering Handbook; see References Section for full citation.)

Bin and base, credit: Dafoe

Monitoring and Management

Composting

Now that the mortality are properly enveloped or incorporated the process of composting takes 4-12 months depending on mortality size and mixture. During this phase it is a good practice to monitor the piles and intervene at the appropriate times, i.e.: when additional cover is needed or pile is emitting odor. Some operators will leave a marker where the last mortality is located to avoid accidentally disturbing the active site. The process of composting mortality is passive. This phase of the process should not be disturbed for three to six months depending on animal size. During this time, microbial activity from bacteria and fungi are performing their function by reducing the carcass to a homogenous organic material. Most of the easily decomposed tissue is virtually “gone” within 6-weeks. Fungi need the extra time to continue working on the remains. The pile can be disturbed for mixing, watering and stockpiling for curing after 4-6 months in the passive phase.

Temperature

Temperature management is a critical component of successful composting. Monitoring involves both taking and recording the temperature of your compost piles and making observations about their condition. A long-stem thermometer inserted into the pile after construction is the first step in monitoring. Reaching temperatures of 120-150 F, assures the operator of effective composting. A compost thermometer has a long probe (18-60 inches long) in order to measure the internal temperature of a compost pile.

Temperature is a reflection of microbial composting activity in the pile. When microbes feast, they multiply and give off heat. If temperatures are cool (<80o F), there is some reason why the microbes are not thriving. Temperature should be checked every couple days during the first 7 to 10 days after covering the mortality. Thereafter it is wise to check on temperatures at least weekly. Graph the temperature as a function of time and you’ll see it rise quickly up to about 130-160o F and then decline gradually. Under normal composting conditions, when temperature declines for a week or more, it is time to turn the pile in order to aerate it. This typically results in rising temperatures again, if conditions remain optimum. Temperatures in the 140 to 160 degree range, held for 48-72 hours are necessary to sterilize weed seeds and destroy pathogens.

However, when composting mortalities, the piles need to sit, undisturbed for a few weeks or months; temperatures will be quite variable during this time. Because of the high moisture content of a large carcass, there will be pockets of wet anaerobic degradation around animal; a proper pile will naturally correct this. Once the pile is turned it should be evaluated for water content (see below) and temperatures tracked for another month. In the Rocky Mountain west, times to achieve this status range from 4-8 months. This final period after turning should continue composting prior to curing. Bones will continue to break down in this phase, which follows more traditional composting recommendations.

Moisture Content

You can use the squeeze test described previously to evaluate whether your compost piles in the post-turning final stage have adequate moisture. If piles entering the final stage do not have enough moisture, the best time to add water is at the time of turning. In static piles (the beginning stage of mortality composting), turning and watering do not typically take place unless there is a problem (lack of temperature rise, for example). Because of this, it is even more important to get the moisture content right from the start. Moisture of 40-60% in the carbon based compost materials is ideal. If necessary, add water to the compost material you are using to bury the carcasses in a few days prior to or on the day you start the carcass composting (prior to adding the cap). The cap will reduce evaporation from the piles and help to maintain optimum water levels.

Moisture Management

If carbon is very dry, add moisture to the layers as you are building the pile. The compost feedstock should be at 40- 60% moisture (this has proven to be a good range for arid climates). Piles/ windrows can be shaped to shed moisture or include it depending on climate and weather conditions. Piles with peaked tops will shed moisture in high precipitation areas. Creating a flat top will allow moisture that falls on the pile to soak in. Creating a trough will allow moisture to collect and soak in. When piles are working efficiently it is hard to add moisture, as much of it is released into the atmosphere.

Other

In addition to temperature and moisture content, it is important to monitor your piles regularly for scavenger activity, odors, and flies. These issues are addressed in the Issues section of this document.

Curing and Storage

Curing is the stage of composting that occurs after the thermophilic (hot) process has ended and mesophilic (warm) conditions are established. Curing usually takes place by simply allowing the compost to sit for an additional period of time on-site. Winter conditions can potentially prolong this phase of the composting process because very cold conditions may prevent adequate microbial activity.

There must be sufficient aeration and moisture during this phase as oxygen loving organisms are at work to further breakdown the organic material. Anaerobic conditions can still occur so it may be necessary to turn or mix the pile during this phase. Curing also gives organisms more time to breakdown some of the larger bones to a more brittle and smaller form that is easier to incorporate into the soil. Bones can be screened out of compost that will be land applied, and introduced into new piles to continue breaking down. There should not be a large increase in temperature after this mixing but some increase in temperature is expected and is a good sign of microbial activity and the curing phase is underway. Observe the pile temperature after mixing with a long-stem thermometer to assure the pile is proceeding according to plan. The pile should be left for another 4 to 8 months. By this time very few bones will remain visible, large bones will be brittle, and the material can be appropriately used.

Storage of compost increases the size, or footprint, of the composting site. However, it is a necessary component to the system that provides maximum flexibility in the end use of the material. Compost should only be stored within the protected composting area after the curing phase when little to no risk of continued heating will occur. Slightly more storage area may be needed if active composting occurs during the winter months when potentially less mass is lost during composting as compared to summer. The goal with storage is keep it from becoming a nuisance but accessible for land-application, or recycling into new mortality piles when the time is right.

Site Selection and Environmental Management

Good stewardship of the land means taking the necessary steps to prevent possible problems that could negatively impact water, air, and soil quality. Most states have regulations regarding management practices for handling wastes; often dependent on type of waste, and size or tonnage of the operation. Best management practices are encouraged for all composting operations even if exempt from specific regulations. The information below can help identify some best management practices that should be considered.

Site Selection

When choosing an appropriate site for composting there is a variety of general characteristics that should be considered.

An appropriate site will:

- Help to protect water and soil quality,

- Protect bio-security (prevent spread of pathogens or disease),

- Prevent complaints and negative reactions of neighbors,

- Decrease nuisance problems, and

- Minimize the challenges in operating and managing the composting operation.

In addition, the location of the composting site should be:

- Above/out of floodplains

- Easily accessible (in most weather),

- Require minimal travel,

- Be convenient for material handling, and

- Maintain an adequate distance from live production animals to help reduce the risk of the spread of disease.

Although specific site selection requirements may vary from state to state, the location should have all-weather access and allow for storage of carbon/compost materials, and should also have minimal interference with other operations and traffic. The site should also allow clearance from underground or overhead utilities for safe maneuvering of equipment.

Consideration should be given to visibility and location of traffic patterns required for moving dead animals, adding carbon/compost materials, and removing finished compost. An adjacent storage area for compost materials (i.e., sawdust, straw, crop residue, etc.), will eliminate the need to transport amendments from a distance. In the arid west, moisture may be needed in the final composting steps, once the mortality has been consumed. Consider how you may get water to the site for this purpose.

A compost site should be located in a well-drained area (but not well drained soils) that is at least 3 to 4 feet above the high water table level, at least 300-500 feet from sensitive water resources (e.g., streams, ponds, wells, etc.), and that has adequate slope (1-3%) to allow proper drainage and prevent pooling of water.

The base of the compost site should consist of soil with low permeability. If the predominant soils create a wet muddy working area, a compacted layer of sand or gravel about 15 cm (6 in) thick could be used to improve the working surface. If protecting ground water is a concern, a constructed concrete pad or imported clay pad may be necessary. Seek local guidance regarding soil type, groundwater issues, and related management options. Engineered pads and heavy use area protection practices pay for themselves during periods of extreme weather conditions. Similar recommendations would apply to where cured and finished compost is stored.

Composting areas should be located, when possible, with consideration to wind patterns that minimize potential odors or dust being carried to neighboring residences. Although composting does not usually generate odors, regular handling and composting of dead animals may be offensive to neighbors.

Stormwater Management

Most states have recommendations or requirements for stormwater management, especially for permitted facilities. There are three basic principles to consider in site management regarding runoff: 1) prevention, 2) collection, 3) distribution. Preventing water from running onto the composting site helps keep the site manageable and is likely the law in many states. Run-on water is diverted from the compost area with berms, ditches or swales. This, in turn, minimizes the amount of runoff generated by the compost site, especially in the arid west. Orienting windrows (when used) perpendicular to the slope of the site allows the windrows to absorb moisture and prevents erosion in-between. Situate the compost site to avoid water ponding, and facilitate collection/movement of excess water to a buffer, vegetative filter strip or an engineered storage structure if the run-off will be significant. If a composting area uses a run-off collection pond, the effluent should be treated in accordance with the laws and best management practices associated with land application of liquid animal waste. It will likely be evaporated or land-applied at agronomic rates.

Big Rain Events—Permitting Issues, Applicable Rules

Big rains can bring big problems even for small operation. Adopting conservation practices that lessen the effects of big rains can decrease non-point source pollution of nearby streams or shallow groundwater, reduce impact of odors, and decrease the likelihood of the spread of disease or pathogens. The National Oceanic and Atmospheric Administration has developed different time scale maps for storm events such as the 24-hour, 25-year precipitation maps that can help with planning (http://hdsc.nws.noaa.gov/hdsc/pfds/index.html). USDA-NRCS can also assist with assessing runoff potential and recommending conservation practices.

Dust Control

Evaporation generally exceeds precipitation, in the arid west, on a yearly basis; traffic in the composting areas may generate dust. Dust from soil can be avo