Structural and Rodent Fumigation in Montana Agricultural Systems

Fumigants are used to manage insect and rodent pests in hard-to-control agricultural areas including grain storage structures and burrows. For efficient and safe fumigant application, pesticide applicators must follow proper safety and application procedures.

Last Updated: 02/19by Amy Bowser, MSU Extension Pesticide Education Technician; Dr. Cecil Tharp, MSU Extension Pesticide Education Specialist, Dept. of Animal and Range Sciences; and Stephen M. Vantassel, Vertebrate Pest Specialist, Montana Dept. of Agriculture

THIS PUBLICATION DISCUSSES STRUCTURAL

and rodent fumigation in Montana and covers safety precautions, application procedures, dosage calculations, fumigant management plans, storage and disposal. While this publication presents available fumigants for use in Montana, it focuses on aluminum and magnesium phosphide products as they represent the most commonly used fumigants in Montana agricultural structures.

Fumigants are used to control insect pests in structures used to store agricultural commodities like these silos. Pixabay.com

Fumigants are pesticides whose active ingredient is applied in gaseous form, versus liquid or solid forms, to control insect and rodent pests in agricultural areas. Fumigants work by releasing a toxic gas or vapor which spreads throughout a contained space. A certain concentration of gas must be reached for a specific amount of time to control the target pest.

Some fumigants such as carbon monoxide are not federally registered and do not require a license for private applicators to purchase or use, however ignitable gas cartridges are federally-registered general use pesticides, which in Montana require a pesticide license to apply commercially or as a government employee. Methyl bromide, sulfuryl fluoride, and phosphide products are federally-registered restricted use pesticides due to their high acute toxicity to humans and animals. Applicators using these fumigants must have a restricted use pesticide applicator license to purchase or use. Proper safety and application procedures must be followed to ensure a safe and effective application. Always read and follow the pesticide product label prior to application.

Two benefits of using fumigants are the negligible residual grain contamination after treatment and the ability to target pests in areas where other pesticides are not successful. However, there are disadvantages to using fumigants including toxicity to humans, lack of long-term control, amount of preparation required for a successful application, labor and equipment requirements, and sensitivity to temperature and humidity.

Target Pests, Safety and Toxicity When Using Aluminum or Magnesium Phosphide

Aluminum and magnesium phosphide fumigants are used to control insect and rodent pests. For a list of Montana stored grain insects and further identification, see the ‘Pest Management for Grain Storage and Fumigation manual’ at http://www.pesticides.montana.edu/documents/manuals/FumSeed.pdf. Aluminum phosphide fumigants are commonly sold as solid pellets or tablets, while magnesium phosphide comes in strips or plates. When the pesticide pellet or tablet contacts ambient moisture in the atmosphere, hydrogen phosphide gas is released, also known as phosphine gas. The rate of gas release is proportional with temperature and humidity at the time of application (i.e. high temperature and/or humidity equal a high rate of gas release).

Phosphine gas is toxic to all mammals including humans. Symptoms of exposure include tightness in the chest, ringing in the ears, faintness, dizziness, nausea, vomiting and diarrhea. Overexposure can lead to coma and death.

Phosphine gas is extremely flammable. In high concentrations it will spontaneously ignite above its lower flammable limit of 1.8% (18,000 ppm). Phosphine gas is also reactive and very corrosive to metals including copper, silver, gold and platinum. Always be aware of high humidity when opening flasks of aluminum phosphide pesticide; high humidity can cause a flash (flame) to be emitted from a flask for less than a second. Always try to purchase only what is needed for the given task and avoid storing fumigants.

Reading the Pesticide Product Label

Applicators must always read and follow the pesticide label. The label contains specific instructions pertaining to the exact product purchased. Fumigants often come with supplemental documentation called the Applicator Manual.

A PROPER RESPIRATOR IS REQUIRED FOR ALL FUMIGATIONS. READ THE LABEL TO DETERMINE THE RESPIRATOR NEEDED FOR YOUR SITUATION.

This document is considered part of the label and the information within is required to be read and followed. The pesticide label contains information on pests controlled, safety protocols, required equipment, application rates and procedures, successfully executing a fumigation, and fumigant management plans.

GLOVES MUST BE DRY WHEN HANDLING ALUMINUM PHOSPHIDE PELLETS OR TABLETS.

Personal Protective Equipment

The pesticide product label details the personal protective equipment (PPE) required for application. In general, PPE requirements for fumigant applications are dry gloves made of cotton or other material and a respirator. Do not use chemical resistant gloves or outerwear as any fumigant trapped inside will release phosphine gas.

One of the most important aspects of fumigation PPE is a proper respirator. Many respirators on the market are not suitable for fumigants so it is very important to read the fumigant label to determine the exact type of respirator to buy.

The required respirator depends on phosphine gas concentrations and is stated on the label. At phosphine gas levels from 0.3 to 15 ppm a full-face mask with replaceable phosphine gas canister is required unless concentrations can be verified to be below the time weighted average (TWA). The time weighted average is 0.3 ppm for 8 hours, while the short term exposure level (STEL) is 1 ppm over 15 minutes. If the levels of phosphine gas are unknown or are above 15 ppm, a self- contained breathing apparatus (SCBA) is required. The SCBA has a full-face mask attached to an oxygen canister with a limited air supply. Any applicator required to wear any respirator must have a medical evaluation and fit test prior to using a respirator.

Fumigant Gas Monitoring and Equipment

Many fumigant labels require the use of gas monitoring equipment during a fumigation and while aerating after a fumigant application.

Personal electronic gas monitors are small devices worn on your person to protect yourself from harmful gas concentrations. When a threshold of a specific gas has been reached, the monitor will sound an alarm indicating the gas concentration has reached unsafe levels signaling you either need to leave the vicinity or use proper respiratory equipment as listed on the label. The benefit of a gas monitor is the device continuously reads gas concentrations, so the user is notified immediately if they are being exposed to dangerous concentrations. This device should not be used for reading fumigant concentrations within a structure unless the applicator is wearing a SCBA.

Gas detector tubes consist of a pump and single-use glass tubes. Both tips of the glass tubes must be broken prior to insertion in the pump where air is drawn through the tube. The tube will change colors if gas is present and will indicate the concentration of gas in ppm. This type of equipment can be used from a distance using hoses, which reduce the hazard of fumigant exposure. Gas detector tubes are ideal for monitoring gas concentrations within a structure.

There are both high- and low-range detector tubes available for the most common fumigants. High-range detector tubes are used during fumigations to ensure proper gas concentrations for pest control are reached. Low-range detector tubes are used to determine worker safety during and after fumigation, as well as monitoring aeration after a fumigation has occurred.

Choosing and Purchasing Equipment

Prior to purchasing any equipment, read the pesticide labels of any products you anticipate using to determine what monitoring equipment is needed and if there is a specific sensitivity required. For example: gas measurements may need to be taken at a sensitivity of 1.0 ppm or as low as 0.1 ppm. Knowing this information will ensure purchase of the correct equipment. Fumigant labels frequently list suggested manufacturers of gas monitoring equipment. These recommendations will help narrow down choices of products on the market.

In many situations it is ideal for an applicator to use both a personal gas monitor and gas detector tubes to monitor fumigant levels within the structure or treatment location. Both monitoring devices may not be necessary for all fumigants or applications. Discuss what options are recommended for the specific fumigant being used with the fumigant manufacturer or pesticide dealer.

When to Monitor Gas Levels During a Fumigation

It is important to monitor gas levels during a fumigation. For structural fumigations, testing will alert you to the penetration rate and if there are any leaks in the structure being fumigated. For burrow fumigation, testing ensures phosphine gas levels in the air at the treatment area have not risen to dangerous levels.

Take fumigant readings at regular intervals to monitor the gas levels. During a structural fumigation it may be beneficial to understand, prior to fumigating, what gas levels must be reached to ensure proper pest control. If proper gas levels are not reached due to a leak or insufficient application rates an applicator can expect poor pest control; thus, prompting expensive secondary applications.

Successful gas monitoring depends on the structure or burrow being fumigated, and the fumigant being used. The best place to obtain information regarding how to conduct monitoring during the fumigation is to read the pesticide label and applicator manual in detail. Describe in detail how gas levels will be monitored in the fumigant management plan. Proper planning prior to fumigation will ensure you are ready with appropriate equipment at specific times and are able to understand how to analyze and record the information.

The location must be monitored prior to re-entry to ensure gas levels are below minimum threshold levels indicated on the pesticide product label (i.e. 0.3 ppm for aluminum or magnesium phosphide products).

Fumigant Management Plans

Fumigant management plans (FMP) are designed to help the applicator follow all label requirements, plan a safe application and are required to be completed by law. FMPs consist of a written description of the steps to be followed in the actual fumigant application. The steps for aluminum/magnesium phosphide products include:

- Planning and preparation, including the purpose of the fumigation, the type of fumigation, a site assessment, the fumigant to be used, and environmental and commodity conditions.

- Notification of people in and around the fumigant area, where they can and cannot go and what to do in an emergency.

- Safety monitoring to prevent exposure and fumigant efficacy readings to make sure the fumigation will be successful.

- Notification of local authorities including fire departments and police departments and a plan of what to do if fumigant levels are exceeded.

- Proper sealing.

- Application procedures and fumigation duration.

- Post-application tasks including aeration and gas monitoring.

Completed FMPs are required prior to the fumigation for each structure or burrow system being fumigated and must be kept for two years, in addition to the application records. Easy to use FMP forms can be acquired from fumigant manufacturers, MSU Extension and the Montana Department of Agriculture (MDA). Make sure to get a FMP specific to the type of fumigation being completed as the steps for burrow fumigations are different than structural fumigation. A generic Montana rodent fumigant management plan can be downloaded online at https://agr.mt.gov/Topics/Vertebrate-Pests; while a Montana structural fumigant management plan can be downloaded online at http://www.pesticides.montana.edu/documents/references/finalstructuralfmp2017.pdf.

General Approach to Fumigating a Structure Using Phosphine Gas

Montana private applicators may use fumigants to control pests in grain bins and silos that are empty or are being used to store raw agricultural commodities such as grain. Special procedures need to be followed to ensure success at controlling pests in this environment.

Site Suitability

Fumigants must be used in acceptable, enclosed spaces to maintain the proper gas concentration to control the target pest. To determine if a site is acceptable, applicators must keep in mind fumigants can easily escape through cracks, vents, holes, other permeable areas and should never be used in areas which cannot be acceptably sealed and fully secured to prevent entry of humans, livestock, and other domestic or wild animals. Applicators must also ensure the site has proper environmental conditions including temperature, humidity and air circulation. Finally, sites need to be prepped prior to fumigation to remove any items or equipment which may become damaged by the fumigant especially when using aluminum or magnesium phosphide, which are corrosive to metals.

Determining Volume, Application Rates and Exposure Periods

Because fumigants treat a space instead of a surface, determine the volume of the space or bushels of commodity to be treated. If tarping, measure only the bushels of seed or volume under the tarp, otherwise measure the volume of the entire structure. Volume calculations can be found online at http://www.pesticides.montana.edu/documents/manuals/FumSeed.pdf under Appendix 4: Grain Storage Mathematics on page 31.

Example of sealing fans prior to fumigation. Photo from Degesch America

Application rates are based on the cubic feet or bushels of commodity treated and are generally listed as number of pellets or tablets per 1,000 cubic feet or per 1,000 bushels. Often a label will list an application range; use the higher rate when there is a severe pest infestation, lower temperatures, or sealing is expected to be partially effective. Do not apply more than the maximum allowed dosage.

Labels will list the exposure period, or the length of time required to control pests at a specific temperature. Phosphide fumigants will not work properly below 40°F. The minimum exposure periods range from a minimum of two to eight days for pellets and three to 10 days for tablets based on temperature.

Sealing

Most structures to be fumigated will need to be sealed to achieve high enough gas concentrations to control the target pest. Holes, cracks and other areas where gas can escape allow the fumigant to move outside the structure, which lowers the concentration inside and poses a safety risk for humans and animals outside the structure.

TO ENSURE AN EFFECTIVE APPLICATION THE STRUCTURE OR COMMODITY MUST BE COMPLETELY SEALED TO MAINTAIN GAS CONCENTRATIONS.

There are several methods to seal a structure. One method is to use plastic sheeting to cover the entire treatment site. This may be useful when fumigating corrugated grain bins that require significant sealing of eaves, doors, etc. More airtight spaces may only require taping of seams and cracks. Also tape and seal off anything within the space that may be damaged by the fumigant. Applicators commonly use plastic sheeting, caulk and/or spray insulation to seal cracks, crevices, ducts, doors, etc.

Placarding at Fumigation Site

Fumigation sites must have warning signs at all entrances (i.e. field entrances for rodent fumigations; doors and hatches for structural fumigations) during the exposure and aeration periods with specific wording as listed on the product label. Doors and entrances to all structures being fumigated must be locked to prevent entry into the space.

Application for Structures

Phosphine gas fumigant labels require at least a two-person application with one applicator having a pesticide license.

For an effective application, aluminum phosphide pellets and tablets need to be distributed throughout the grain mass using a probe to disperse the product throughout the commodity. Probe in a grid system to distribute the fumigant uniformly throughout the grain mass.

Magnesium phosphide strips or plates should be placed around the structure or on the grain mass in a way to allow free flow of air to the fumigant.

Aerating

Once a fumigation is complete, the gas must completely dissipate before allowing access to the fumigated area. Aeration is discussed on all product labels and it is the applicator’s responsibility to follow the instructions for their specific product.

When aerating a structure wear required respiratory equipment while opening all vents and unsealing the structure. Make sure downwind areas of the structure are kept clear to prevent exposure to people and animals. Use gas detection devices to monitor gas levels within the structure and outside the structure. Once gas levels are below 0.3 ppm, placarding can be removed, and respiratory equipment is no longer required. Continue to aerate for several hours to prevent fumigant buildup due to desorption of the commodity. Venting for 48 h is recommended for food/feed commodities to reduce concentrations within grain mass to below tolerance levels of 0.1 ppm.

Sod plugs may be used to cover a burrow opening to contain fumigant gases. Photo provided by S. Vantassel.

General Approach to Fumigating Rodent Burrows using Phosphine Gas

Montana private applicators may use phosphide fumigants or ignitable gas cartridges to control burrowing rodents in non-residential settings on property they own, rent or lease. Do not fumigate burrows of non-target burrowing species including the endangered black-footed ferret, burrowing owls, weasels, swift fox and badgers. Always read the product label prior to application. FMPs must be completed for restricted use pesticide fumigation of rodent burrows. Treatment of prairie dog towns requires additional steps prior to treatment.

Application

Phosphide fumigants are labeled for rodent burrows located beyond 100 feet of human-frequented buildings. Phosphide products used for managing burrowing rodents are also prohibited on single and multi-family residential properties and nursing homes, schools (except athletic fields), daycare facilities, and hospitals. Be sure treated burrow systems do not have openings within the 100-foot buffer including under any building. Signs must be posted at all entrances to treated areas and left for a minimum of 48 hours after treatment.

To treat open burrow systems, place 2-4 tablets or 10-20 pellets into each entrance to be treated. Use lower rates for small burrows or when soil moisture is high. Use higher rates for large burrows or when soil moisture is low. Pack the treated entrance with crumpled paper and soil. Seal all untreated entrances with soil. Inspect treated areas 1-2 days following treatment for signs of activity. Re-apply fumigant to reopened burrows.

To treat closed burrow systems, locate the main underground runway by probing 12-18 inches from a fresh mound. Apply 2-4 tablets or 10-20 pellets through the probe hole. Apply at a higher rate when soil moisture is low and apply at a lower rate when moisture is high. Seal hole. Check for activity in two days and re-treat if activity is present.

Storage and Disposal of Phosphine Fumigants

Storage and disposal considerations are discussed in detail on the product label and should be considered prior to fumigation. Empty containers with no dust present need to be triple rinsed, punctured and disposed of at a landfill. Some phosphide gas fumigants come in resealable containers and can be stored for future use. Fumigants need to be stored in a placarded, locked, dry, well- ventilated area away from heat and food products. Do not store in buildings where humans or animals may reside. Make sure containers are tightly sealed prior to storage.

Leftover fumigants which cannot be resealed need to be deactivated prior to disposal, as well as PPE contaminated with unspent phosphine dust. Deactivation must occur outside in a secure and posted area to keep unauthorized people away. Always wear proper PPE while deactivating fumigants. Applicators have two options for deactivating left-over product or contaminated equipment.

Wet Deactivation

To deactivate unreacted phosphide fumigant, you must create a 2% solution of water and low-sudsing detergent or surfactant (4 cups in 30 gallons). Wear respiratory protection and slowly add the product while stirring. Do not cover the container.

Dry Deactivation

Dry deactivation is useful for small quantities of unreacted fumigant. The easiest way to deactivate the pesticide is to extend the fumigation period. Four to seven pounds of unspent dust may be placed in a one- gallon bucket to finish reacting. Larger amounts of dust may be placed in porous bags. Place the bucket and bags away from humans and animals and do not cover. Residual dust will be left over after the product has been deactivated. This grayish-white dust can be disposed of onsite by burial or spreading over the land in a secure area away from buildings. It can also be disposed of at a landfill.

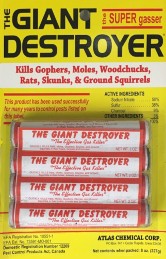

Example of an ignitable gas cartridge available for use in Montana. Photo provided by S. Vantassel.

Additional Fumigant Options

Ignitable Gas Cartridges for Rodent Burrow Fumigation

Ignitable gas cartridges do not require a pesticide license for purchase as they are a federally-registered general use pesticide. Ignitable gas cartridges contain combustible materials including sodium nitrate, sulfur and charcoal. When ignited, carbon monoxide gas and other toxic gases are produced. Ignitable gas cartridges are registered for use controlling woodchucks, yellow-bellied marmots, ground squirrels and prairie dogs in open fields, non-crop areas, rangelands, reforested areas, lawns and golf courses. Use for control of pocket gophers is not recommended as there is little evidence of effectiveness.

To be effective, the cartridge must burn thoroughly, and the gasses must be contained in the burrow. Adjacent burrow openings must be filled with soil to contain the gas. Once the fuse is lit, the cartridge must be placed as far down the burrow as possible and then the burrow opening must be covered with soil. It is best to fumigate after rain or when soil moisture is high. Care should be taken when using this method in dry conditions as the cartridges burn with some intensity. Within five days of application check burrows for signs of activity and re- treat if needed.

Never use ignitable cartridges under or near buildings. Wear gloves when igniting the cartridge. Stay upwind and avoid breathing the fumes. Store cartridges in a secure and dry location.

Carbon Monoxide

Devices are available on the market which pipe carbon monoxide gas into rodent burrows. These devices do not require a pesticide license for private applicators to purchase or use. A few examples include P.E.R.C.®, GopherX® and Cheetah Rodent Control Machine. Carbon monoxide is highly toxic to humans and these devices should not be used in or near human-occupied buildings. The MDA recommends the following minimum distance from structures: 150 feet when targeting pocket gophers, 100 feet for prairie dogs, and 20 feet for ground squirrels unless the device instructions recommend a larger distance. While using the device, stay upwind and avoid breathing in fumes. Headaches are a common indicator of carbon monoxide poisoning. To have a successful fumigation, burrow entrances need to be covered with soil to maintain carbon monoxide levels within the burrow for the time specified by the manufacturer.

Methyl Bromide

Methyl bromide has been in use since the 1930s to target a wide variety of pests, however due to its ability to deplete the ozone layer, production of products containing methyl bromide stopped in 2005, except for use in emergency or critical cases. Leftover stocks can legally be used if the product is currently registered for use in Montana. Methyl bromide is a highly toxic, restricted use pesticide and applicators must have a pesticide license to purchase and apply the fumigant. Methyl bromide is extremely hazardous to humans. Read and follow all instructions on the pesticide label.

Sulfuryl Fluoride

Sulfuryl fluoride has been used for more than 50 years for fumigating insects and rodents within non-food/ feed structures; however in 2004 another pesticide product was registered as 'ProFume' by DOW Agro for fumigating over 50 food commodities including wheat and barley. This product is highly toxic and can inhibit normal metabolic functions in high exposure scenarios. DOW Agro offers mandatory trainings for the use of this product due to its inherent toxicity. Product use in Montana private agricultural systems is low. This is possibly due to mandatory additional trainings, expensive monitoring equipment, and need for specialized equipment for proper delivery when compared to phosphine products. It should be noted this product is highly effective if used properly, and a superior alternative to phosphine products if phosphine resistant insects are present.

For More Information

References

Aluminum and Magnesium Phosphide R.E.D. Fact Sheet (1998). United States Environmental Protection Agency.

Controlling Burrowing Rodents with Burrow Fumigations (2018). Montana Department of Agriculture.

Fumigation Training Manual. University of Kentucky Cooperative Extension Service.

Pest Management for Grain Storage and Fumigation: Seed Treatment (2004). Montana Department of Agriculture.

Registered Field Rodenticides in Montana (2017). Montana Department of Agriculture.

Pesticide usage suggestions provided in MSU Extension materials are intended to serve only as a guide and are published for educational purposes. If any suggestions conflict with a product label, follow the product label instructions. Read and follow all product labels carefully.