Silage in Montana

Silage is a high-moisture method of preserving forage. Generally, forages utilized for silage are harvested and then stored at moisture contents above 65 percent, but this number can vary depending on the type of forage.

Last Updated: 11/18by Emily Meccage, Extension Forage Specialist; Jeffrey Chilson, Extension Agent Roosevelt County; Danielle Peterson, MSU Forage Research Lab Manager; Rachel Endecott; American Simmental Association Director of Youth Development

INTEREST IN ENSILING FOR FORAGE PRESERVATION

has increased in Montana in recent years. The relative speed of the harvesting process, along with the generally improved nutrient-quality production per acre associated with silage, makes it appealing to many producers. Additionally, ensiling has the potential to reduce labor costs where ensiling machinery is available due to replaced manual labor during harvest and storage.

Silage is a high-moisture method of preserving forage. Generally, forages utilized for silage are harvested and then stored at moisture contents above 65%, but this number can vary depending on the type of forage. In Montana, this means that forage can be harvested and stored within 24 hours, and depending on conditions, potentially in a matter of hours.

Benefits of ensiling include greater flexibility in harvest management and more efficient use of labor. Harvesting at high-moisture content helps to improve leaf retention, thereby preserving forage quality. Many forage and grain species, including those that are generally used for hay production, can be ensiled. Choice of species is often dependent on individual producers’ needs, and type of livestock being managed. The various options available in Montana will be discussed later in this document.

Why ensile?

There are several advantages to preserving forage as high- moisture silage versus low-moisture hay. One of the main advantages is the reduced time required for harvest. In the semi-arid Montana environment, most crop species require less than 24 hours for the small reduction in moisture that is necessary before storage. In years where rains are scattered throughout the summer months, this can be a relatively easy method of preserving the nutrients within forages. These forages are usually harvested at earlier maturities to optimize forage quality, which can help spread the harvest window. Furthermore, harvest dates can be very flexible, and decided later on in the season. If a producer notices that the grain market is low, they can choose to harvest part, or all, of their grain field as silage instead.

Additionally, research suggests that more leaves are usually retained during the harvesting and storage of ensiling compared to dry hay. This means that nutrient quality is quite high for ensiled forages. Other research has also shown that digestibility and palatability are higher in ensiled forages compared to dry forages due to the high moisture content. Overall, improved energy and crude protein (CP) production per acre with silage are increased compared to preserved hay.

Corn being harvested and chopped prior to storage where the ensiling process will begin.

TABLE 1. Effect of forage conservation (silage vs. hay) on nutrient quality of various forage species

| Conservation method | Forage species | Dry Matter (DM) | Crude Protein (CP) | Total Digestible Nutrients (TDN) | Crude Fiber (CF) | Acid Detergent Fiber (ADF) | Neutral Detergent Fiber (ADF) | Source |

| Silage | Alfalfa | 31.0 | 16.2 | 21.4 | 50.7 | --- | --- | Shepherd (1954) |

| Hay | 81.7 | 14.1 | 24.5 | 47.9 | --- | --- | ||

| Silage | Mixed grass1 | 27.3 | 14.1 | --- | 29.9 | --- | --- | Coulon et al. (1997) |

| Hay | 84.9 | 14.6 | --- | 30.1 | --- | --- | ||

| Silage | Mixed grass2 | 23.3 | 16.5 | --- | --- | 51.2 | 29.3 | Shingfield et al. (2002) |

| Hay | 85.8 | 14.2 | --- | --- | 64.0 | 32.4 |

1 - 28% meadowgrass, 22% perennial ryegrass, 15% other species (white clover, dandelion, and bromegrass). 2 - Mixed timothy and meadow fescue

However, there are some disadvantages that should be considered. Ensiling often requires specialized equipment and storage facilities, which can increase initial costs. Bunkers, silos, plastic or large tarps or bags are recommended for maintaining the anaerobic environment necessary during storage, and can be a large initial expense. Creating silage “mounds,” in which no protection is provided, is not recommended, and will result in extremely high dry matter and quality losses. The outer part of the mound, along with the face (or the outer edge) of the mound are exposed to oxygen, and become spoiled and essentially unusable for animal feed due to mold and palatability issues. Silage that has been exposed to oxygen is the main cause for spoilage and increased storage losses in silage compared to hay.

Another disadvantage is that the anaerobic microbes required for the fermentation process require nutrient substrates, mainly water-soluble carbohydrates (WSC) and CP. In some cases this can decrease the CP and soluble carbohydrate content of the silage when fed to animals, however the forage is overall still a high-quality product (Table 1). Because of the requirements for an anaerobic environment, there is generally more intensive management requirements. Poor management practices can result in increased spoilage and greater storage losses.

Choosing to produce silage requires careful consideration of management and financial capacity. Silage production requires large capital costs and investments. Choppers, wrappers, and storage facilities can be expensive, and may require additional financing to get started. Selling and moving silage can also prove difficult and costly, as transporting off-farm without large amounts of spoilage may be difficult. However, for many producers, this initial capital investment can be offset by increased production and quality of product, which translates to higher animal returns.

How is silage preserved?

Silage is preserved when bacterial fermentation creates organic acid by-products that lower the pH of wet forages. Organic (carbon based) acids, such as acetic and lactic acids, as by-products also inhibit the growth of other deleterious microorganisms. However, it is important that the fermentation environment is anaerobic to limit the appearance of unwanted organisms and to achieve a stable pH for storage.

During ensiling, anaerobic bacteria, such as lactic acid bacteria (LAB), convert carbohydrates into energy and organic acids. The LAB can be divided into two categories: homofermentative and heterofermentative. Homofermentative LAB produce primarily lactic acid while heterofermentative LAB produce both lactic and acetic acid. Lactic acid is responsible for the sharp decline in pH during ensiling. Acetic acid is helpful in inhibiting yeast and mold growth, both of which are undesirable. A third acid that may be produced, butyric acid, is generally considered undesirable. Butyric acid is produced by clostridial bacteria, and can be the result of too much moisture, not enough carbohydrates available for LAB consumption, or environments that inhibit LAB fermentation (to be discussed later).

Factors impacting silage preservation

Type of forage

Forage species play an important role in silage quality and production. Both perennial and annual species can be used to make silage. Common species include corn, alfalfa, wheat, barley, and many cool-season perennial grasses. Almost any species that is used for hay production can also be used for silage production.

Additionally, new and improved varieties of several species are now available with improved digestibility and decreased lignin content. Sorghum, sudangrass, including hybrids, millet, and corn, have low lignin forage varieties known as brown midrib (BMR) forages.

SIX PHASES OF SILAGE FERMENTATION AND STORAGE

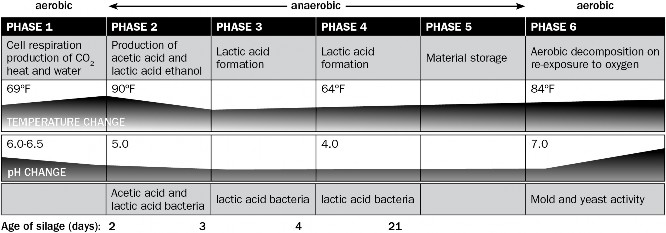

The ensiling process can be divided into six phases. Phases 1 and 6 are aerobic, or include oxygen, while phases 2-5 are anaerobic.

Phase 1: Plant cellular respiration continues to utilize oxygen to metabolize plant carbohydrates. It is important that this step is completed as rapidly as possible, in order to preserve the maximum soluble carbohydrate content, and therefore digestibility. By-products of cellular respiration are carbon dioxide, heat, and alcohol. During this phase WSC levels will decrease while fiber levels increase. Phase I should be expected to last approximately 3-5 hours after packing.

Care should be taken so that heating is not excessive during the ensiling process by ensiling at the appropriate moisture content. A good rule of thumb is that heating should not exceed 20°F above ambient temperature. If heating is excessive, it can result in loss of available protein, as well as inhibition of LAB fermentation. After phase I, the oxygen should have been completely utilized and anaerobic fermentation can commence.

Phase 2: Anaerobic fermentation begins, producing primarily acetic acid, which decreases pH from 6 to approximately 5. Additionally, there is also a marked decrease in soluble carbohydrates as bacteria convert them to organic acids, helping to decrease pH. This pH decline creates an environment favorable to LAB.

Phase 3: Once lactic acid is the primary acid produced from the LAB, acetic acid production will begin to slow and eventually stabilize. The goal of ensiling is to reach a lactic acid to acetic acid ratio greater than 4:1. Heat production is also markedly decreased, and pH continues to decrease. This phase is very similar to phase IV.

Phase 4: During this phase, pH begins to stabilize and the LAB begin to enter a dormancy period as the pH nears 4. A pH of 4 is desirable, as yeast and mold activity are prohibited in this acidic environment. Grain silages such as corn and sorghum may reach a pH less than 4 due to their high WSC, while legumes may reach a higher pH of up to 5.5 due to the buffering capacity associated with higher protein content. This means legumes require larger amounts organic acids to achieve the desired pH.

Phase 5: Known as the storage phase, this begins once temperature and pH changes have stabilized, which is generally reached by day 21. This phase can last an indeterminate amount of time, as there is minimal microbial activity. The silage has been effectively preserved, and will remain so until oxygen is introduced during the feed-out phase. Issues might be experienced, particularly if there is excessive moisture or insufficient WSC for fermentation. In these cases, clostridial bacteria populations may increase, producing butyric acid. Butyric acid creates a displeasing and strong odor, increases pH to 5 or greater, and is unpalatable to livestock.

Phase 6: Also called the feed-out phase, which occurs once the silage is exposed to oxygen. Aerobic spoilage can result in dry matter losses up to 50%, so the main goal of this phase is to decrease exposure to oxygen as much as possible. The main cause of spoilage is degradation of lactic acid by yeasts, which can produce mycotoxins that are detrimental to livestock health and production. Face management, or managing exposure to oxygen, will be described later in this document.

TABLE 2. Estimated forage quality of various forage species after ensiling.

| Forage Species | Moisture % | CP (% DM) | NDF (% DM) | ADF (% DM) | Lignin (% DM) | TDN (% DM) |

| Barley | 66.4 | 12.1 | 54.8 | 34.7 | 4.8 | 60.6 |

| Wheat | 65.9 | 12.7 | 56.5 | 36.6 | 4.8 | 59.1 |

| Triticale | 67.0 | 13.9 | 58.6 | 38.2 | 4.7 | 57.8 |

| Sorghum± | 71.2 | 9.1 | 60.7 | 38.7 | 6.5 | |

| Sudangrass | 69.4 | 12.3 | 61.4 | 40.3 | 5.8 | 53.5 |

| Oatlage | 66.16 | 12.7 | 55.9 | 38.5 | 5.3 | 58.0 |

| Millet | 65.1 | 12.3 | 61.9 | 40.3 | 6.0 | 53.0 |

| Corn | 66.9 | 8.2 | 43.0 | 25.5 | 3.2 | 67.7 |

| Alfalfa× | 62 | 15.5 | 45.0 | 35.0 | 5-15 | 58.0 |

| Bromegrass | 58.0 | 9.0 | 71.1 | 43.1 | 55.0 |

These species were bred for decreased lignin production, and are commonly used in silage production in place of conventional breeds. A study in Texas found that BMR sorghum silage had an average increase of almost 1% CP, and a decrease of almost 2% ADF and approximately 3% decrease in NDF. Additionally, lignin was decreased from 4.4 to 3.6%, demonstrating the utility of these types of forages in forage production. A new type of alfalfa, reduced-lignin alfalfa is also available, however studies are still being conducted to evaluate expected nutrient quality, so those values are not included here.

Moisture content

Moisture content can play a major role in overall forage quality, depending on the species that is being ensiled. It is important to harvest and store at the right maturity in order to maximize forage quality. Type of storage facility can also influence ideal moisture content. Generally, horizontal silos will have better quality forage if stored at higher moistures, around 65-70%. Conventional upright silos may be around 60-68% depending on type of forage. Recommended moisture for bagged silage is usually between 60-70%. If placing in a pile or stack, moisture levels closer to 70% are recommended.

Plant Maturity

As plants mature, digestibility and nutrient concentrations of the forage material decrease while yield increases. For example, alfalfa can be over 22% CP at bud and decrease to the mid-teens at full maturity (100% bloom). Small grains such as wheat can be over 15% CP at boot and decrease to less than 10% by dough, which will have a significant impact on silage quality. However, with small grains and other species such as corn, the seeds can be a great source of energy. Still, as those seeds mature, the digestibility of the starch may decrease. See Table 3 (page 5) for recommended maturities at harvest of different classes of forage.

The ideal maturity at harvest depends on producer goals and needs. Generally, for beef cattle production, it is ideal to maximize production versus quality. For this reason, we harvest at a later maturity, i.e. early heading for grasses or soft dough for small grains. Care must be taken to not wait too long to harvest, otherwise optimal yield production will be surpassed and nutrient quality and digestibility will begin to severely decline. Care should be taken with some annual crops such as sorghum and sudangrass, as both prussic acid and nitrates may be an issue.

Availability of water soluble carbohydrates (WSC)

Water Soluble Carbohydrates (WSC) are an important substrate for microbial production. Moisture can be a major confounding factor with WSC levels, as the more wet the forage is, the lower the pH required to create adequate fermentation, and therefore the more sugar (WSC) that is required. Legumes such as alfalfa are especially prone to incomplete fermentation due to low sugar levels, so it is especially important to maintain an anaerobic environment, and ensure moisture at harvest is adequate.

Chop length/packing density

Chop length can have major implications in overall roughage value and animal performance. Chopping length of ? to ¾ of an inch for corn is ideal, and a range of ? to ½ inch is recommended for alfalfa. If forage is chopped too long, it cannot be packed as tightly, increasing risk of oxygen inclusion, resulting in increased heating and molding. If chopped too fine, wastage and loss increases, and overall animal performance may decline. It is important to evaluate chopping length throughout the process to ensure that it is adequate for the particular species being used.

|

TABLE 3. Recommended maturity timing for harvest of common species used for silage production. |

|

|

Species |

Recommended maturity for harvest |

|

Corn |

¼- ½ milk line |

|

Alfalfa |

Bud to early bloom |

|

Cool-season Grasses |

Boot to early heading |

|

Small grains (i.e. wheat and barley) |

Boot to soft dough |

|

Annual crops (i.e. sorghum and sudangrass) |

At least 36” or around soft dough |

Nutritional value

Forages commonly harvested for silage in Montana include corn, alfalfa, and small grains such as barley or wheat. These crops are commonly irrigated given the arid climate. Estimated nutrient content for various species of forage used for silage are detailed in Table 1 (page 2). Because of the high moisture content of ensiled forages, it is important to remember that the amount fed will be much larger than when animals are fed the same forage in dried form.

For example, let’s compare barley hay and barley silage. If the barley hay contains 88% dry matter and the barley silage contains 35% dry matter and a ration calls for 20 pounds of feed per animal on a dry matter basis, how much of each would we provide the animal (as-fed basis)? It would take around 23 pounds of barley hay (20 / 0.88) and 57 pounds of barley silage (20 / 0.35) to provide the same 20 pounds of dry matter intake. Care should always be taken to ensure that you have accurate moisture estimates, as well as quality analysis to develop rations that will meet livestock nutritional needs.

Anti-nutritional factors

Anti-nutritional factors should always be a concern when feeding any forage. Mold and mycotoxins are usually the main concern with silage. If not managed properly, aerobic microorganisms can become prevalent throughout the stored silage, which may produce mycotoxins that are harmful to consuming animals. Face management as well as proper harvest and storage management methods need to be observed to decrease risk.

Ensiling can be a solution to reducing anti-quality factors that may otherwise be present in forage preserved as dry hay. Studies have shown that ensiling can decrease the risk of nitrate toxicity anywhere from 0-60%, potentially reducing toxic levels of nitrates to a safer level. However, silage should still be tested prior to feed out to ensure nitrate levels are not an issue, particularly in cereal and warm-season grass silage.

Similar to nitrate toxicity, ensiling has been found to reduce the risk of prussic acid toxicity in livestock. Care should be taken to allow at least three weeks for the fermentation process to remove the cyanic acid, the causative factor in prussic acid poisoning, to safe levels. However, not all research has found favorable effects of ensiling on prussic acid levels. Silage should be tested prior to feed-out to ensure levels are not toxic to animals. Several labs offer prussic acid testing; however, it is often expensive and inconclusive due to the nature of the cyanic acid, and its volatility. Even when overnighted to a lab for analysis, cyanic acid levels may decrease significantly and fail to reflect the actual values the animal would be consuming. Several agents around Montana have been using a strip test, similar to a pH test, to evaluate levels. Contact your local Extension agent or Extension specialist to learn more about this test.

Pricing silage

When pricing silage for sale, it is important to account for the increased moisture content of the product. Methods for accurately determining moisture content include sending samples to a commercial lab for analysis or by simply using the microwave. If sending samples off to a commercial lab, care must be taken to ship samples as quickly as possible to prevent loss of moisture resulting in inaccurate measurements. Using the microwave method is simple and requires a few easy steps to determine moisture content. First, measure the weight of a sample prior to placing in the microwave. Second, microwave the material for 30 seconds at a time, until two consecutive readings report the same weight. Third, calculate the percent dry matter (and conversely moisture) using the following equation:

% Dry Matter = (weight of fresh sample – weight of dried sample) / weight of fresh sample

In order to compare on a similar basis to preserved hay, always use the dry matter weight. If using a forage analysis for quality comparison, make sure to always use the nutrients in the dry matter column. Refer to MSU Extension Montguides Collecting a Forage or Feed Sample for Analysis (MT201610AG) or Forage Analysis Interpretation (MT201609AG) for more information on how to read ar forage analysis. Use pricing scales for similar quality forages, and price silage on the dry matter basis, to ensure the buyer is getting treated fairly and you are receiving adequate compensation.

Forage being loaded into a pit ready to ensile.

Storage Method

Generally, two different methods of storing silage are considered in Montana: horizontal silos and stack silage; haylage and baleage are excluded. Horizontal silos can be aboveground in the case of bunkers or stacks, or belowground like with pits and trenches. Stack silage methods are usually used to store excessive amounts of silage and hold over for longer periods of time until ready for feed-out. For stack silage, the leading edge of the stack should be at approximately a 30-degree angle and packed lengthwise. Potential spoilage with these stacks can be high, but immediate covering and anchoring can help to reduce spoilage. Research has found that domed stacking is the most efficient shape, but at least four inches should be removed daily to avoid excessive spoilage.

In the case of trench silos, trenches are usually dug into a slope with an end open to allow for draining and tractor access. Walls should be sloped to avoid caving, especially if soil is sandy and prone to instability. Reinforcements such as concrete or treated wood can be used to avoid walls collapsing. For bunker silos, which are most common in Montana, flat or mostly flat areas are desirable. Walls for the bunker can be constructed from concrete, wood, timber, or straw bales. The most important factor is preventing oxygen exposure and spoilage from any side. If treated wood is to be used with any of these methods, make sure that it is not treated with preservatives, and it is ideal if it can be covered with plastic to prevent any moisture or acid penetration.

The front slope should be as steep as possible to help prevent spoilage during feed-out. Continuously pack layers at two feet intervals to prevent excessive oxygen from infiltrating the pile. Polyethylene (6 mm thick) or reinforced plastic is ideal for covering any bunker, and white is preferable due to UV resistance and less variation in temperature changes in the pile underneath it. Some producers may choose to not cover their bunkers or pits and allow a “crust” to form from the spoiled silage that is exposed. This spoiled silage may contain mold and other anti-quality factors, therefore care must be taken to avoid feeding this layer and should be discarded. The spoiled silage layer can be upwards of six inches thick, resulting in significant amounts of silage lost. Inoculants and preservatives can be used to reduce the spoilage, however, they are costly and will still result in significant amounts of silage lost when stored in this manner.

Feeding Out

Face management

The goal for feeding silage is to maintain an anaerobic environment as much as possible. This becomes especially important during feed-out. Decreasing exposure to oxygen, and limiting ensiled forages exposure will help to preserve nutrients and reduce spoilage. Research has found that if face management is marginal, spoilage and dry matter losses can be as high as 10%, resulting in significant losses to the producer. An important strategy in appropriate management is maintaining a smooth outer surface with no cracks from dried or exposed forage, or to prevent exposure entirely with coverings. This helps to decrease the overall exposed area, as well as decrease risk of avalanches, and improve water retention in the case of open silage pits or bunkers.

Reducing losses requires rapid use of the silage that has been exposed to oxygen and the environment. Research has found that even in densely-packed silage bunkers, air can move three feet into the pile. To mitigate this uncover only three days of feed at a time, at maximum. Another way to think about it is that on average, remove 6-12 inches per day during the rainy season and 18 inches per day during any season with higher rainfall. This will have an impact on how deep or tall the bunker or pit will be loaded. If you don’t use a lot of silage each day, consider a shallower pit or smaller bunker to reduce spoilage; this can have impacts, however, on how much silage is exposed in the case of uncovered bunkers, or how much tarp or cover is needed if enclosing the silage.

If using a front-end loader to remove silage from the pile, remove from the top rather than the bottom, trying to keep the entire exposed face as smooth as possible. Safety should also always be considered. Keeping the face smooth will also reduce the likelihood of a silage avalanche. Never create a silage pile that is higher than equipment can reach. On average the height of a silage pile should only be about 12-14 feet, depending on equipment type.

Always keep an eye on the pile. If excessive amounts of silage are becoming spoiled at a faster rate than can be fed, re-evaluate the feeding plan. It may also mean a need to discard some of the spoiled silage so livestock performance is not affected. Poor management of the silage pile can result in significant dollars lost, as well as contribute to wasted time and effort.

TABLE 4. Advantages and disadvantages of silage storage methods

|

Method |

Advantages |

Disadvantages |

|

Concrete bunkers |

|

|

|

Drive-over piles |

|

|

|

Hillside pits |

|

|

TABLE 5. Advantages and disadvantages of several types of silage additives and inoculants.

|

Additive |

Advantages |

Disadvantages |

Examples |

|

To download more free online MontGuides or order other publications, visit our online catalog at our store, contact your county or reservation MSU Extension office, or e-mail orderpubs@montana.edu. Copyright © 2023 MSU Extension We encourage the use of this document for nonprofit educational purposes. This document may be reprinted for nonprofit educational purposes if no endorsement of a commercial product, service or company is stated or implied, and if appropriate credit is given to the author and MSU Extension. To use these documents in electronic formats, permission must be sought from the Extension Communications Coordinator, 115 Culbertson Hall, Montana State University, Bozeman, MT 59717; E-mail: publications@montana.edu The U.S. Department of Agriculture (USDA), Montana State University and Montana State University Extension prohibit discrimination in all of their programs and activities on the basis of race, color, national origin, gender, religion, age, disability, political beliefs, sexual orientation, and marital and family status. Issued in furtherance of cooperative extension work in agriculture and home economics, acts of May 8 and June 30, 1914, in cooperation with the U.S. Department of Agriculture, Cody Stone, Director of Extension, Montana State University, Bozeman, MT 59717 |