Getting Started with Beef to School

This MontGuide examines models, challenges, solutions and recommendations for getting locally-grown beef into school food service programs in Montana.

Last Updated: 06/18by Thomas Bass, MSU Extension Animal & Range Sciences; Carmen Byker-Shanks, MSU Education, Health & Human Development; Demetrius Fassas, NCAT-ATTRA; Janet Gamble, MSU Education, Health & Human Development; Katie Halloran, NCAT-ATTRA; Aubree Roth, MSU Education, Health & Human Development; Joel Schumacher, MSU Extension Agricultural Economics & Economics Mallory Stefan NCAT-ATTRA;

MONTANA HAS APPROXIMATELY 2.5 MILLION

cattle, roughly 20 state- and federally-inspected beef processors, and about 145,000 students across 821 public schools. Considering these statistics, Montana is an ideal location to implement and evaluate local beef to school procurement programs. Many school foodservice directors are motivated to provide nutritious Montana agricultural products, including local beef, to students while supporting local ranches and meat processing facilities. While some school foodservice, rancher, and processor partnerships have already developed beef to school programs that are mutually beneficial, others have struggled to find a price point, delivery system, or sourcing method that works for all parties involved. This publication presents an analysis of successful models and effective strategies for beef to school programs.

Why Local Beef?

Communities and consumers are interested in local beef for a number of reasons, which the Montana Beef to School Project aimed to identify. The project was a three-year collaborative research and outreach endeavor supported by USDA, and engaged with several Montana beef producers and processors, schools, and the Montana Beef to School Coalition. The research identified a variety of motivations, perceptions, and beliefs about beef to school (B2S) programs. Motivations for implementing a B2S program identified in surveys and interviews of Montana B2S stakeholders are summarized as follows:

- Quality: School foodservice staff perceive local beef as higher in quality when compared to other non-local beef sources due to the taste, freshness, and less water that cooks off during preparation. Future research is needed to better understand quality in this context and to determine actual measurable differences between commodity beef and the local beef

- Food Literacy: Learning about Montana beef increases food and agriculture literacy among students, school staff, and communities. There are opportunities for education about the direct connections between Montana’s landscape, culture, and food that coincide with serving local foods in schools

- Nutrition: Some producers and school foodservice staff perceive local beef as more nutritious due to the short supply chain and traceable label. Conventional food service beef or commodity market beef (part of the USDA Foods Program) is often an aggregated product from multiple cattle raised and finished in different places. Because of geographic proximity in local systems, it may be easier to visualize the kind of feeds and inputs used during production, processing, and meal preparation. Some respondents Some producers and school foodservice staff perceive local beef as more nutritious due to the short supply chain and traceable label. Conventional food service beef or commodity market beef (part of the USDA Foods Program) is often an aggregated product from multiple cattle raised and finished in different places. Because of geographic proximity in local systems, it may be easier to visualize the kind of feeds and inputs used during production, processing, and meal preparation. Some respondents believed this supply chain created a more nutritious product. Nutritional profiles were not compared between local and conventional or commodity beef in this project.

- Community: Schools, producers, and processors are often proud of, and like to be involved in the local food system. Conventional and niche producers, large or small, can participate in a local B2S program. Shortening the supply chain in a B2S program is perceived as enhancing community connectedness and draws more direct lines between producers, processors, students, and families.

- Environment and Animal Welfare: Some respondents held negative perceptions of large outof-state feedlots, and with the great distances cattle and meat often travel. Though food miles, the distance commodities and food travels, can be a poor metric of environmental sustainability or animal welfare, fewer miles traveled for cattle and meat was a perceived social and environmental benefit. As Montana is primarily a cow-calf state, where cows are bred and calves are raised on range or pasture every year, there was appreciation for range and pasture-based systems, as well as smaller feedlots utilizing local feeds which may include barley, sugar beet pulp, and alfalfa.

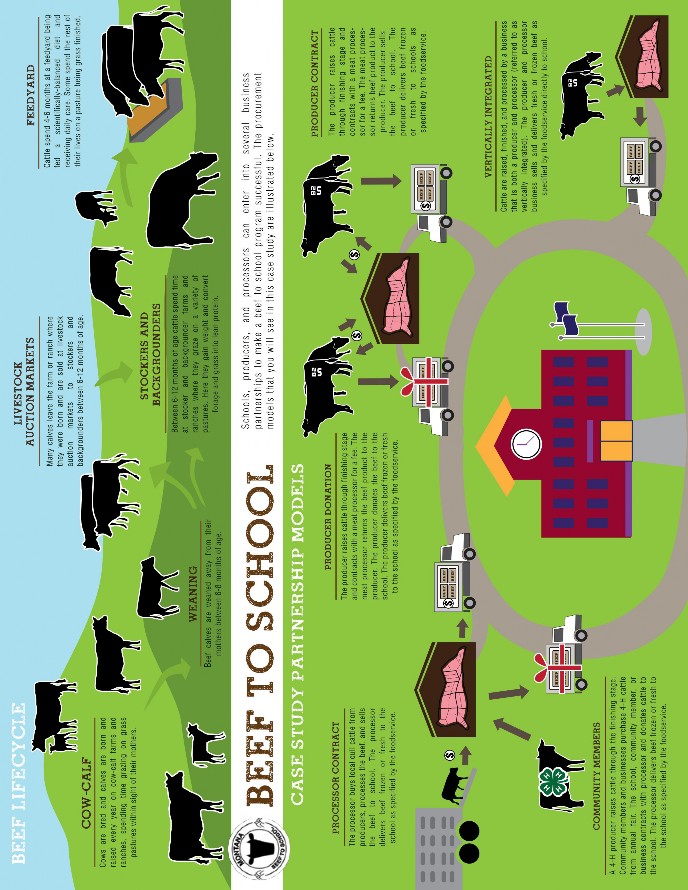

Montana Beef to School Models

Vertically Integrated

Bear Paw Meats of Chinook, MT, is a family-owned, vertically-integrated cattle, feeding, auction, processing and retail meat enterprise. Vertical integration means that a single company owns and operates several parts of the supply chain required to produce the final product; in this instance, the Buck family controls cattle production, cattle finishing and meat processing, in addition to wholesale and retail meat distribution. Bear Paw Meats operates a state-inspected processing facility, allowing their products to be sold to any buyer within the state of Montana.

Since 2008, Bear Paw Meats has been selling products to K-12 schools in their region for use in school meal programs, with Hinsdale School as an early and important partner. Karla and Dexter Buck, owners of Bear Paw Meats, believe that the quality of their burger comes from locally-sourced forages and feeds, and their close control over the whole process. With their vertically-integrated operation they are able to control the feed ration and create a consistent product for all of their customers.

Processor-based

Lower Valley Processing, Inc. is a family-owned, state-inspected meat processing facility located south of Kalispell, MT. The Plummer family has operated the business since it opened in 1974. Lower Valley’s core business is custom processing. Lower Valley also purchases live animals (primarily cattle and pigs), processes the animals, and then sells the meat to food establishments and direct to consumers.

Whitefish, Kalispell, and Somers/Lakeside Districts are the primary school partners of Lower Valley. To establish a personal relationship and understand Lower Valley’s business, Kalispell School District’s foodservice director initially brought cooks and other staff to tour Lower Valley’s facility. Lower Valley Processing buys approximately two cull cows per week for the school districts and pays the ranchers based on the carcass weight and current meat prices. They add their processing fee to this price to determine the final price to schools.

Increasing school demand has allowed Lower Valley to invest in additional personnel, a new patty machine, and a refrigerated truck, benefitting not just B2S, but all of their customers. Partners in this B2S example expressed comfort in understanding this short, transparent supply chain. Local cattle are selected for processing just days before the beef is delivered to the school. The beef is delivered weekly, fresh not frozen, and it is usually cooked and consumed that week.

Producer or Ranch Branded

Lazy SR Ranch is located in the Shields River Valley north of Livingston, MT. After requests for local beef increased around 2012, Lazy SR started holding a number of calves each fall for direct marketing. These calves are owned by Lazy SR until they are ready to be slaughtered and processed for retail sale. These cattle 3 Barriers Solutions Cost Focus on affordable cuts and products (ex. ground, burger patties, roasts...) Consider and seek local cull cows Investigate donation potential Use wholesome extenders in recipes (ex. lentils, mushrooms, puréed vegetables) Budget local beef over a month or semester of meals, not per meal Heat and serve kitchens Seek an inspected kitchen to brown or pre-cook as appropriate for further distribution in district Creating and sustaining interest Educate, advertise, promote and give credit to producers, processors or other relevant partners on signs and menus Kitchen convenience Clearly communicate processing preferences and package quantities (sizes) Storage Plan ahead for receiving product and designating freezer space, particularly if a whole animal is involved Finding cattle or beef Consult local food directories, restaurants and grocers for/about local suppliers, check government listings for inspected processors, and inquire with staff and students about family ranches are grass fed until they reach about 850 pounds and are finished on grain rations at a local feedlot until they reach about 1,300 pounds. Once the animals reach market weight, they are processed by a local meat processing facility.

Lazy SR Ranch worked with Livingston School District during the 2015-2016 school year. The district primarily orders hamburger. Occasionally, Livingston School District purchases other products, such as roasts. Lazy SR’s business model allows the ranch to reduce their calf sales and finish more cattle to increase their beef supply as demand increases. Lazy SR Ranch values the educational worth, in addition to the business opportunity, of selling to schools.

Donation Model

Ranchland Packing is a federally-inspected processor operating out of a 15,000 square foot facility in Butte, MT. The business offers slaughter, fabrication (breaking the carcass into wholesale and retail cuts), and further processing. For Montana, Ranchland Packing is a larger processor; their USDA federal inspection status allows for both intrastate and interstate commerce. Ranchland Packing has worked with schools since about 2012. Their primary partnership for K-12 schools is the Dillon School District, 64 miles to the south. In this partnership, they are a third-party supply chain partner.

Dillon School District sources animals through donations from community members, 4-H auction buyers, and ranchers. Ranchland Packing processes the donated cattle for a fee. Dillon School District began to use local beef for hamburgers on their school menus years ago when businesses in the community began bidding on and purchasing show animals from 4-H students during the fall fair. Once purchased, the businesses decided to donate the animals, sometimes including the processing fees, to the Dillon School District.

Ranchland Packing’s processing schedule with Dillon School District depends on when a community member donates a live animal to the school. Ranchland Packing is given a limited timeframe in which to meet the school’s order. Silo Meats of Dillon assists with delivery between Butte and Dillon using their refrigerated truck. If planned carefully, school contracts have the potential to help distribute processing more evenly throughout the calendar year. Though the school business is a small portion of their overall business, Ranchland Packing welcomes expansion in school customers.

| Barriers | Solutions | |||||

| cost |

|

|||||

| Heat and serve kitchens | Seek an inspected kitchen to brown or pre-cook as appropriate for further distribution in district | |||||

| Creating and sustaining interest | Educate, advertise, promote and give credit to producers, processors or other relevant partners on signs and menus | |||||

| Kitchen convenience | Clearly communicate processing preferences and package quantities (sizes) | |||||

| Storage | Plan ahead for receiving product and designating freezer space, particularly if a whole animal is involved | |||||

| Finding cattle or beef | Consult local food directories, restaurants and grocers for/about local suppliers, check government listings for inspected processors, and inquire with staff and students about family ranches |

From Challenges to Solutions

Establishing a B2S program can be challenging. However, Montana communities have been creating local solutions and finding success. This section will outline some common limitations or barriers, and provide recommendations based on our research findings and what B2S participants and stakeholders from around the state have shared.

Cost

Local beef tends to be priced higher than other sources of beef that schools have access to, including the USDA Foods Program. In Montana, cost is the primary barrier to establishing B2S programs. The fee charged to students for a school lunch is often less than $3 per meal. To put this in perspective, if hamburger is $4 per pound, then a 1/5 pound hamburger patty would cost $0.80. The hamburger patty alone is over 25% of the total meal cost. Combine this with the cost of other ingredients (including required items from at least two other food groups) and the labor cost for the kitchen staff, and it is easy to see that schools are price sensitive about sourcing their ingredients. At the time of this research (2015-2017), case study participants shared that the average cost for beef from the USDA Foods Program and non-local markets for schools ranges greatly from free (through USDA Foods) to $3 per pound. Depending upon the local beef to school model, the cost for local beef ranged from free (donation models) to $4 per pound at the time of the case study. Current prices for local beef range from 15-20 percent higher than conventional beef. Some solutions to cost issues are outlined:

- Affordable cuts and ground: Producers and processors can utilize schools as a market for lower value cuts, such as hamburger, while selling the higher value cuts, such as steak, to other markets. High value steaks are a relatively small proportion of a processed beef animal; stew meat, hamburger, roasts, and other lower value cuts (tongue, ox tail, heart, ribs, etc.) make up the majority of harvested meat. Some restaurants provide markets for the high value steaks but are not able to provide a market for all of the hamburger. Because the restaurants purchase the higher value cuts, the schools may be able to partner and purchase hamburger at a price that fits within budget constraints.

- Cull animals: Cull cattle, animals eliminated from the breeding herd, can be utilized to overcome some of the cost constraint. These animals tend to sell for lower prices than prime age (18 to 30 months of age) animals. At a weekly auction in Montana (summer 2017), cull animals sold at a 15-30% discount to prime age steers. This discount allows the finished beef product to also be sold at a lower price to the end customer.

- Financial and livestock donations: Donations are another option used by some communities. In this model, donations can include the animal itself, the cost of processing, and/or financial support to source local beef. Donations can occur occasionally, or on an ongoing basis and help the school significantly in balancing the budget. Donation models rely on the generosity of one or more parties and are sometimes accompanied with the opportunity for a tax deduction for the donor.

- Budgeting over time, not by the meal: Like many animal proteins, local beef is a costly portion of the school meal. Some school foodservice staff recommend budgeting school meals over a semester or year, rather than by meal, in order to balance the cost of more and less expensive food products. In many schools, the foodservice balances cost of local beef by pairing more expensive items such as the local hamburger patties with less expensive items such as USDA Foods sliced carrots within a meal. They also cut costs by using their staff’s creativity to add less expensive ingredients to meals (e.g., lentils to beef chili thereby extending quantity and reducing cost – see below) or reducing the number of pre-processed items the foodservice uses in general.

- Extending beef in recipes: Wholesome extenders to beef products may also be desired to modify nutritional profiles and to reduce the cost of local beef products. Extenders often get wrapped up in controversial discussions and misunderstandings. However, there has been some savings success in Montana from adding vegetable, legume, and even mushroom extenders to local beef products in certain recipes. This can be an economical way to extend local beef value and utilize other local foods.

Technology, Kitchen Convenience

The technology limitations of Montana processors prevent the production of certain products at some schools. For example, a school may not have kitchen facilities or staff capacity to brown large amounts of ground beef, and would require pre-cooked beef crumble. In such a scenario, a food-hub (local food processor/aggregator/distributor) with inspected kitchen facilities may be a source for local pre-cooked beef crumble. Likewise, a school district with a central kitchen may be able to cook large amounts of ground beef and distribute to smaller kitchens. Almost all Montana processors can provide schools with frozen or fresh hamburger patties separated by wax paper; these are relatively convenient to use.

In most cases, kitchen staff will not need additional training or new recipes to utilize local beef. Switching from purchasing 10-pound frozen hamburger packages from a large distributor to 10-pound frozen packages from a local beef supplier would not change or impact kitchen processes; however, switching from pre-made seasoned meatballs to making meatballs 5 from scratch is not as simple. Recognizing which beef products are available in similar packaging is helpful in identifying opportunities for kitchen staff to switch to a local product.

Storage can be an issue at the processor, school, or at a meat depot used by some ranch-branded beef lines. Consider when beef can be ordered and where it will be stored. This is a significant issue for some, but it can be overcome with planning and communication.

School Size and Foodservice Models

In Montana, student enrollments range from less than 100 students to over 5,000 students per district. Additionally, school meal programs also vary by the number of schools served by a single kitchen. In some school districts a central kitchen may provide meals for several elementary schools, a middle school, and a high school. In other districts, each school within the district may have a stand-alone lunch program. Some schools may also have a model that blends these two options, in which some items are prepared in a central kitchen while others are prepared at each school. School lunch program attributes such as size and district kitchen networks will have to be considered on a case by case basis when investigating local beef procurement and use.

Another factor that impacts the number of lunches that a particular lunch program will serve is the average meal participation rate of students. A school with 500 students is likely to serve fewer than 500 meals each day. Some students choose to bring their own lunch and some schools have an “open campus” policy that allows students to leave school property to eat lunch. Both of these options reduce the number of students participating in the school lunch program and will influence purchasing decisions for local foods, including beef. In the case studies, Montana schools reported better lunch participation on local beef days, which presents an opportunity for local beef advocates.

Logistics and Availability

Availability of a local supplier and the logistics of purchasing from that supplier are significant factors in establishing local food purchases. Most lunch programs are able to easily order a wide variety of products from an institutional food distributor that will deliver to the school on a regular basis. Large or small volumes of a diverse range of products are easily available. Ordering an extra case of an item or trying a new item is as simple as adding to their order. Switching to a local supplier for some, or all meat products, involves placing an order with an additional supplier and arranging for an additional delivery, and sometimes processing, to take place. Even if ordering and delivery is smooth and efficient, it is an extra step in the process.

Inspection

Montana has approximately 20-25 processors, inspected for retail sales, that can slaughter and process beef. This is a wealth of processing capacity compared to other states. Federal or state inspection is required for providing beef to Montana schools. Most of the processors in Montana are state inspected by the Montana Department of Livestock, allowing for intrastate commerce; the remainder are federallyinspected by USDA, allowing for interstate commerce in addition to sales in the state.*

General Recommendations

Start Small: Even schools with robust local beef programs started small. Respondents reported success in beginning with special events, or pilot programs like a monthly Montana hamburger day, Montana Harvest of the Month activities, or other curricular and educational tie-ins. Starting small is practical, can demonstrate what is possible, and promote sustainable growth of a long-term B2S program.

Work with Processors: Schools and producers should try to understand the processor’s needs and schedule in advance. Fall is a busy time for processors, so calling early and clearly communicating needs will help establish a good relationship early on. Keeping appointments and communicating potential delays between all parties is important.

Schools that are receiving a whole animal will need to work with the processor ahead of time to determine how to best process the animal and ensure the most useful cuts or products are received. School foodservices and the processor may create a “cut sheet” to facilitate desired processing into the future. While the cut sheet will indicate how the animal should be processed, one should keep in mind that culled animals are best used for ground beef and roasts.

Recipients or purchasers of whole animals should have realistic expectations for how much meat an animal will yield. In order to estimate the cost per pound of meat, schools will also need to estimate the yield for the live animal. A live animal that weighs 1,200 pounds might produce 500-600 pounds of beef depending on factors such as age, breed, processing and other factors (similarly, some estimate meat yield to be 40% of live weight).

Processors, schools, and beef companies can have storage limitations, so plan meat pick-up or delivery promptly. Storage and delivery logistics should be settled before processing, which helps all parties utilize and plan out their freezer and storage space. Good communication and common courtesy has been found to be the most beneficial element in building strong, positive relationships between producers, processors and schools. Finally, address all questions and concerns early so both parties have the same understandings (Coffey, 2017).

Market, Advertise and Give Credit: Promote local beef by advertising on the school’s social media accounts, school website, newsletters, and bulletin boards around the school. Mark the use and source of local beef on school menus. Encourage parents to join for lunch and highlight the use of local beef and the producers and processors who are working with the school. Get students involved by educating them on what local beef is and where their beef is coming from. Reach out to local newspapers and share information about the farm to school program and give credit to the local producers and businesses involved. Word of mouth is a great way to advertise the use of local beef and to give credit to producers and processors.

Conclusion

The success and sustainability of B2S programs depends on the support and commitment of school foodservices, producers, and processors. Around the state of Montana, successful B2S programs are ones where producers and processors provide a high quality product within the school’s budget. Each B2S program described here functions differently in that mission, based upon the relationship built and needs identified between the school foodservice, producer, and/or processor. Overall, B2S programs connect communities with agriculture by providing healthy and local Montana meals to students.

References

Coffey, 2017. Working with your meat processor. IP536. NCAT-ATTRA

This educational guide is based on the same research and shares some language with Chapter 9 - Montana’s Beef to School Project: Making Connections to Enhance Local Agriculture (Byker-Shanks, Bass, and Schumacher) in the volume Institutions as Conscious Food Consumers, edited by Thottathil, S. and Goger A. Elsevier, 2018.

* A caveat to state and federal inspection for selling to schools is the potential role of locally-inspected (e.g., county health department) meat counters, butcher shops, and further processors. Further processors, known as “custom-exempt processors,” are retailers that may purchase state- or federally-inspected beef and further process and package for schools while following additional regulations.

This project was a collaboration with the National Center for Appropriate Technology (NCAT-ATTRA) and Funded by USDA Western SARE. We would like to acknowledge that many Montana school foodservices, meat processors, and cattle producers participated in, and provided input to, this project. Thank you.

This material is based upon work that is supported by the National Institute of Food and Agriculture, U.S. Department of Agriculture, under award number SW15-028 through the Western Sustainable Agriculture Research and Education program under subaward number 140867026. USDA is an equal opportunity employer and service provider

![]()