Integrated Management of Weeds in Dry Peas

In recent years, there has been an increase in market demands for pulse crops. As a result, dry peas (Pisum sativum L.) acreage in Montana has expanded considerably. This Montguide reviews approaches to develop an integrated weed management program in dry peas, an important step to secure yield and crop quality.

Last Updated: 12/12by Fabian Menalled, Cropland Weed Specialist, Department of Land and Environmental Resources

Managing Weeds in Dry Peas

Agronomic and market considerations have sparked an increased interest in diversifying Montana’s cropping systems through the inclusion of pulse crops including dry peas (Figure 1). Besides tolerating drought conditions, cool temperatures and a wide variety of soil types, as leguminous crops, dry peas can help fix nitrogen in the soil. Despite these potential benefits, growers interested in incorporating dry peas into their crop rotation should be aware of the associated weed management challenges and opportunities.

Figure 1. Dry pea (Pisum sativum) plant characteristics

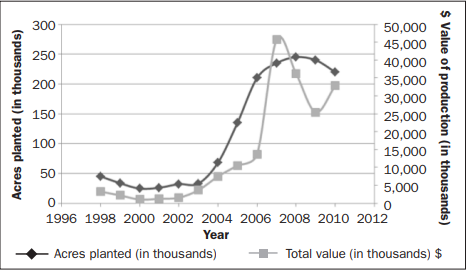

Dry peas are well suited to Montana’s cropping systems with benefits including nitrogen fixation and high water-use efficiency. As consequence, between 1998 and 2010 the number of acres in Montana sown to dry peas increased from 45,000 to more than 220,000 (Figure 2, page 2). However, due to their relative low competitive ability, dry peas carry a high risk of large and frequent yield losses due to inadequate weed management. For example, a wild oat density of 4 plants/ft2 can lead to a 51 percent loss in pea yield. Other studies reported pea yield losses due to wild mustard ranging between 2 and 35 percent and losses due to volunteer barley ranging from 30 to 85 percent. In Montana, difficult to manage weeds in dry peas include broadleaf weeds such as catchweed bedstraw, Canada thistle, Russian thistle, kochia, common lambsquarters, cow cockle, shepherds purse, henbit, mayweed chamomile, wild buckwheat, prickly lettuce, and dandelion.

Growers considering incorporating dry peas into their rotation should develop an Integrated Weed Management (IWM) plan that considers the entire crop lifecycle from preplanting to after the harvest. In doing so, they need to take advantage of cultural, physical and chemical practices to reduce the spread and impact of weeds. The main goals of an IWM program should be to 1) use preventive tools to maintain weed density at a level that does not harm the crop, 2) prevent shifts towards more difficult to control weeds, and 3) develop agricultural systems that maintain or improve crop productivity, farm revenues, and environmental quality.

Designing a successful IWM program requires understanding the different biological and ecological factors that influence the short-, mid-, and long-term dynamics of weeds in agricultural settings. More information on IWM can be found in the MSU Extension Montguides, Integrated Strategies for Managing Agricultural Weeds: Making Cropping Systems Less Susceptible to Weed Colonization and Establishment (MT200601AG), and Weed Seedbank Dynamics & Integrated Management of Agricultural Weeds (MT200808AG).

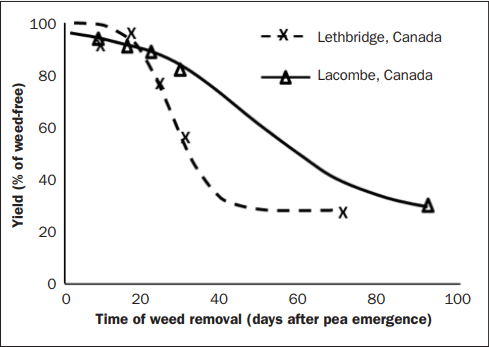

As a general rule, peas require a higher level of weed management than more competitive crops such as wheat or barley. While not enough by themselves, cultural practices including prevention, seedbed preparation, variety selection, proper sowing and crop establishment, insect and disease management, nutrition management, and irrigation scheduling can help decrease the impact of weeds in dry peas. For example, early weed removal in peas could be critical to prevent yield losses and maximize nitrogen uptake and nitrogen fixation dynamics.

Figure 2. Number of acres planted and total value of dry peas in Montana between 1998 and 2010. (Source USDA, National Agricultural Statistics Service.)

Time of weed removal (days after pea emergence)

FIGURE 3. Effect of time of wild oat removal on percentage of pea grain yield loss as Yield (% of weed-free) percentage of weed-free plots at Lethbridge and Lacombe, Canada. (Adapted from Harker and collaborators. 2001. Timing of weed removal in field Pea (Pisum sativum). Weed Technology 15, pages 277-283.)

TABLE 1. Dry pea rotation interval for herbicides commonly used in Montana. These values are for educational purposes only and producers should carefully read labels as rotation intervals vary with soil pH, moisture, temperature, soil texture, and soil organic matter.

| Product | Common name | Rotation interval | Notes |

| Ally XP | metsulfuron | 10 to 15 months | Rotation interval for soil pH of 6.9 to 7.9. Shorter intervals for lower pH values |

| Amber | triasulfuron | No less than 4 months | Pulse crops may be planted after the completion of a successful field bioassay |

| Beyond | imazamox | Anytime | |

| Glean | chlorsulfuron | 24 months | Rotational interval for Oregon, Idaho, and Washington with soil pH below 6.5 |

| Huskie Complete | pyrasulfotole and bromoxynil | 10 months | Huskie herbicide breakdown in the soil is due mainly to microbial action. Under cold and dry conditions, degradation may be slowed |

Peak |

prosulfuron |

10 months |

Conduct a field bioassay if soil pH is above 7.8. Herbicide degra- dation rates vary with soil pH, moisture and temperature, among other factors |

Stinger |

clopyralid |

18 months |

In Montana where soils commonly have less than 2% of organic matter (OM) and there was less than 15" of precipitation within the year following herbicide application, it is necessary to perform a field bioassay. |

| Maverick | sulfosulfuron | 17 to 22 months | Longer intervals are for soils with pH > 6.5. Values for Washington, Oregon and Idaho. |

In a study conducted in Alberta, Canada, Harker and collaborators determined that wild oat emerging simultaneously with the crop began to reduce pea yield two weeks after pea emergence and that the rate of yield reduction varied between locations (Figure 3) (Harker et al. 2001. Weed Technology 15, pages 277-283). While the environmental conditions under which this study took place differ from the ones we experience in Montana, these results can help pea growers time their weed management practices.

Weed impacts can also be reduced by increasing crop competition through increased seeding rates or decreasing row spacing. Studies have shown that increased pea density can help reduced weed biomass. However, producers should ponder the additional cost of these practices as they may not necessarily translate into additional revenues.

Mechanical weed control practices in dry pea, such as post-plant tillage, harrowing or rotary hoeing fields after emergence, represent one tool in an IWM system. Producers should be aware that mechanical weed control practices should be applied with caution to minimize soil erosion and dry pea seedling and roots damage. If harrowing or hoeing is planned, it may be necessary to increase seeding rates because mechanical damage may reduce stands.

Crop rotation is at the core of sustainable agriculture. If properly designed, crop rotation represents one of the most powerful tools to manage pest problems including weeds. Balancing crop rotations can be beneficial for weed management as it provides alternatives to manage weeds across the different crops. Weeds cannot become adapted to any particular environment when they grow in different crops with different characteristics and management requirements. For example, while broadleaf weeds such as kochia, common lambsquarters, and shepherds purse can be difficult to be managed during the pea phase of a diversified rotation, they can be managed during the wheat phase.

A proper crop rotation can confer many benefits beyond weed control. For example, research conducted in Montana by Miller and collaborators (Miller et al. 2006. Agronomy Journal 98, pages 1610-1619) indicated that peas can confer strong rotational benefits to wheat by conserving soil water and contributing soil N, especially when growth was terminated midseason.

It is very important to carefully consider the crop rotation history prior to growing pulse crops as this crop is very sensitive to many herbicides used in small- grain production. The high persistence SU-herbicides commonly used in small grain crops, such as metsulfuron (Ally), chlorsulfuron (Glean), and chlorsulfuron (Finesse), can damage subsequent annual legumes, including dry peas. Due to their persistence, it may be necessary to wait up to four years before seeding peas, depending on the product, application rate, and weather conditions.

The persistence of herbicides in the soil depends on many factors including soil pH, moisture, temperature, soil texture, and soil organic matter. Understanding the risk of crop injury due to soil applied herbicides is particularly important in areas with dry climate and prolonged winters, such as Montana, where herbicides generally degrade slowly (Table 1).

How to conduct a field bioassay

Field bioassays allow producers to evaluate the risk of crop damage due to herbicide carryover. Using typical management practices (tillage, seeding depth, timing for the particular crop, etc.), plant several strips of the desired crop variety across the field which has been previously treated with the suspected herbicide, as well as areas that have not been treated with the herbicide. Plant the strips perpendicular to the direction the herbicide was applied. Place these strips to capture field heterogeneity due to differences in soil pH, texture, organic matter, and drainage. Using the untreated areas as a control, check the crop for visible symptoms of injury, stand reduction, and/or yield reduction. If no herbicide injury symptoms or yield reduction is visible, the field can be seeded with this crop the next growing season after the bioassay. However, if visible herbicide injury symptoms or yield reduction occur, this crop must not be seeded and the bioassay must be repeated the next growing season.

Reducing the risk of herbicide injury in pea crops

Herbicides are valuable tools: they help to control weeds and, if they are residual, can provide season- long control. However, miscalculations in their use can cause crop injury or inadequate weed control. Montana producers know that losing a crop due to lack of rain is an unfortunate but inevitable experience. Losing a crop because of herbicide injury could be as bad as a weather calamity, but it can be prevented. Minimizing the risk of herbicide crop injury is a necessary step for diversifying dryland cropping systems in Montana to include broadleaf crops such as pea, lentil, canola and sunflower.

To minimize the risk of herbicide-injured crops, we need to understand how herbicides function and the several factors that affect their activity. The soils of Montana are unique in that they have lower organic matter and higher pH than is typically encountered outside this region. Therefore, many times Montana’s soils are different than those where herbicide residue studies have been conducted and upon which current recommendations are based.

Researchers and graduate students at Montana State University have evaluated the potential damage that herbicides could cause in crops. To determine the best way to maximize the benefits of herbicides while avoiding crop injury we have assessed carryover effects on different crops and soil types across Montana. This information is available at the Cropland Weed Management website (http://www.ipm.montana.edu/CropWeeds, visit the Prevent and Diagnose herbicide Injury link). More information on approaches to reduce the risk of crop injury due to herbicides can be found in the Montguide, Getting the Most from Soil-Applied Herbicides (MT200405AG).

Chemical weed control can help manage weeds in dry pea fields. However, research and experience has shown that herbicides are most effective when used as part of an IWM program. The applicability and success of herbicides in pea fields depends on the cropping system, land preparation methods, soil conditions, and weed problems. Information on commonly used herbicides to manage weeds in peas is provided in Table 2 (pages 6 and 7) and producers should carefully read and follow product labels prior to using any herbicide. Also, producers should develop a proactive program to reduce the pressure towards the selection of herbicide resistant biotypes.

Preventing herbicide resistance in dry peas

Herbicide resistance is the innate ability of a weed biotype to survive and reproduce after treatment with an herbicide dose that would normally be lethal. In Montana, herbicide resistant biotypes of wild oat, Persian darnel, green foxtail, kochia, and Russian thistle have been found.

To reduce the risk of selecting for herbicide resistant biotypes, producers should rotate among herbicides with different modes of action applied either as tank mixes, premix formulations, or sequential applications. Also, producers should rotate management practices, such as the incorporation of timely cultivation. Finally, crop rotation is an excellent tool to reduce the selective pressure on herbicide resistant weeds. More information on herbicide resistance can be found in the Montguide, Preventing and Managing Herbicide-resistant Weeds in Montana (MT200506AG).

Glossary

Ammonium sulfate (AMS) is an additive recommend by many herbicide labels. AMS often improves weed control, especially when mixed with hard water.

Crop oil concentrate (COC) is comprised of a non-phytotoxic (not causing injury) mineral and/ or vegetable oil and can contain up to 20 percent surfactant. The principal function of the COC is to aid in moving the herbicide across the leaf cuticle and reduce the surface tension of the spray droplets. Crop oils are also effective at increasing spray retention on leaf surfaces and reducing drying times, allowing more time for the herbicide to penetrate the leaf.

Nonionic surfactants (NIS) are specialized additives formulated to improve the performance of herbicides in spray solution. The function of the NIS is to spread the spray droplet evenly over the leaf surface, help it to adhere to the leaf, and increase penetration of the herbicide within the spray droplet into the waxy cuticle that covers the leaf surface.

Sulfonylurea (SU)-herbicides are a family of herbicides discovered in 1975 and widely used in Montana. SU herbicides work by inhibiting a key enzyme – acetolactate synthase – which is unique to plants (not present in humans, animals, insects, birds or fish) and is needed for plant growth. Examples of SU herbicides include sulfosulfuron (Maverick), metsulfuron (Ally), chlorsulfuron (Glean), and chlorsulfuron (Finesse).

TABLE 2. Herbicide options to manage weeds in dry peas. Carefully read product labels before applying any herbicide. (Adapted from Ball, 2012. Pacific Northwest Weed Management Handbook. http://pnwhandbooks.org/weed/).

Annual Grass and Broadleaf Weeds. Preplant incorporated

| Common name (product name) | Rate and Comments |

| Ethalfluralin (Sonalan) | 0.56 to 0.75 lb ai/A (1.5 to 2 pints/A Sonalan HFP). Apply preplant and incorporate. Do not exceed labeled rates because crop may be injured. Do not graze or plant forage crop in treated soil or cut for hay or silage. |

| Imazethapyr (Pursuit) | 0.047 lb ai/A (3 oz/A of Pursuit). Incorporate within 30 days before planting. Do not incorporate deeper than 3 inches. A maximum of 0.047 lb ai/A may be applied to peas. Do not apply more than once per year. Preharvest interval is 60 days. |

| Pendimethalin(Prowl 3.3EC, Stealth, Prowl H2O, and others) | 0.5 to 1.5 lb ai/A (1.2 to 3.6 pints/A Prowl) or 0.7 to 1.4 lb ai/A (1.5 to 3 pints/A Prowl H2O). Use the lower rate on coarse soils. Apply up to 60 days preplant. Incorporate thoroughly, 1 to 2 inches deep. Also controls several broadleaf weed species. |

| Sulfentrazone (Spartan 4F) | 0.07 to 0.25 lb ai/A (2.25 to 8 fl oz/A Spartan 4F). Apply in the spring before crop germinates. Use rate dependent on soil texture and organic matter. Consult label for rates. Preharvest interval is 60 days. |

| Triallate (Far-Go) | 1.5 lb ai/A. Apply preplant or post-plant and incorporate thoroughly 1 to 2 inches deep. Do not graze treated areas. For control of wild oats. |

| Trifluralin(Treflan and others) | 0.5 to 0.75 lb ai/A (1 to 2 pints/A Treflan HFP). Incorporate thoroughly, 2 to 3 inches deep, after apply- ing. Use lower rate on coarse soils. Controls some broadleaf weeds; weak on nightshade, mustard family, and mayweed. Trifluralin may injure stressed crop seedlings. |

| Trifluralin + Triallate (Buckle) | 0.3 to 0.38 lb ai/A trifluralin + 1 to 1.25 lb ai/A triallate as Buckle (10 to 12.5 lb/A Buckle). Apply preplant and incorporate thoroughly, 1 to 2 inches deep, immediately after application. Use the lower trifluralin rate for coarse soils. Do not use foliage from treated peas for feed or forage. |

Annual Grass and Broadleaf Weeds. Pre-emergence

| Common name (product name) | Rate and Comments |

| Imazethapyr (Pursuit) | 0.047 lb ai/A (3 oz/A of Pursuit). Apply immediately after or up to three days after planting. Do not apply more than once per year. Preharvest interval is 60 days. |

| S-metolachlor(Dual Magnum or Dual II Magnum) | 0.95 to 1.90 lb ai/A (1 to 2 pints/A Dual Magnum). Rate depends on soil type and organic matter content. Preharvest interval for hay is 120 days. |

| Sulfentrazone (Spartan 4F) | 0.07 to 0.25 lb ai/A (2.25 to 8 fl oz/A Spartan 4F). Apply in the spring before crop germinates. Use rate dependent on soil texture and organic matter. Consult label for rates. Preharvest interval is 60 days. |

Annual and Perennial Grass Weeds. Post-emergence

| Common name (product name) | Rate and Comments |

| Clethodim (Clethodim 2E, Intensity) | 0.093 to 0.125 lb ai/A (6 to 8 fl oz/A Clethodim 2E). Controls annual and perennial grasses. Always use a petroleum-based crop oil at 1 gal/100 gal. Do not exceed 8 fl oz/A per season. Do not apply more than one application per season or graze. Apply before bloom but not later than 30 days prior to harvest. Application during bloom period may injure crop. |

Quizalofop P-ethyl (Assure II, Targa) |

0.04 to 0.08 lb ai/A (6 to 12 fl oz/A Assure II). Controls annual and perennial grasses. Always use either a nonionic surfactant at 1 quart/100 gal, or a petroleum-based crop oil at 1 gal/100 gal. Do not exceed 14 fl oz/A per season. Pre-harvest interval is 60 days. Do not graze livestock in treated areas or feed forage, hay, or straw from treated areas. |

Sethoxydim (Poast) |

0.19 to 0.48 lb ai/A (1 to 2.5 pints/A Poast). Add 2 pints/A nonphytotoxic crop oil concentrate for ground application to improve leaf penetration. Preharvest interval is 30 days. Do not exceed 4 pints/A product per year. |

Annual Broadleaf Weeds. Pre-emergence

| Common name (product name) | Rate and Comments |

| Metribuzin (Metribuzin 75 andseveral product names) | 0.1875 to 0.375 lb ai/A (4 to 8 oz of a 75% DF product/A). Apply before or after planting, but before crop emerges. Rain or mechanical incorporation is needed. Under dry conditions, incorporate 1 to2 inches. Do not use on coarse soils or soils with less than 1.5% organic matter. Heavy rain after application may injure crop. Preharvest interval is 50 days |

Saflufenacil (Sharpen) |

0.022 lb ai/A (1.0 fl oz/A Sharpen). Early preplant, preplant incorporated or pre-emergence for limited residual broadleaf weed control. Methylated seed oil (MSO) or crop oil concentrate (COC), at 1% v/v+ ammonium sulfate (AMS) at 8.5-17 lbs per 100 gallons, are required for emerged weeds. An early pre-plant application of Sharpen at 1.0 fl oz/A can be made prior to a PPI or pre-emergence application.Sequential applications must be at least 30 days apart. Do not exceed 2.0 fl oz/A during the cropping season. Do not apply when the peas have reached the cracking stage, or after emergence. May be fed or grazed 65 or more days after application. |

Broadleaf Weeds. Post-emergence

| Common name (product name | Rate and Comments |

Bentazon (Basagran) |

0.5 to 1 lb ai/A (1 to 2 pints/A Basagran). Do not apply to peas in bloom. For Canada thistle and yellow nutsedge, use higher rate and apply twice, 7 to 10 days apart. Avoid applying bentazon during prolonged cold weather. Preharvest interval is 30 days. Do not exceed 2 lb ai/A per year. Do not cultivate 5 days before or after applying. |

| Imazamox (Raptor) | 0.031 lb ai/A (4 oz/A Raptor). Apply to dry peas with at least three pairs of leaves before blooming with nonionic surfactant at 1 quart/100 gal. Only one application of Raptor may be made during the season. |

MCPA sodium salt or amine (Chiptox or other names) |

0.125 to 0.375 lb ae/A (0.5 to 1.5 pt/A Chiptox; 0.25 to 0.75 pt/A MCPA amine). Lower the rate as temperature increases. Apply when peas are 4 to 6 inches tall and weeds are less than 2 inches wide or 3 inches high. Do not apply when peas are blooming. Our observations indicate that severe injury could occur and that plants may recover several days after treatment. Do not apply when the temperature is expected to reach 90°F within the next 24 hours. Do not graze or feed. |

| Metribuzin (several product names) | 0.125 to 0.25 lb ai/A (2.6 to 5.3 oz/A of a 75% DF product). Apply once per season to broadleaf weeds less than 2 inches tall or wide. Temporary chlorosis of the crop may occur. Weed control may be reduced if dry conditions persist after treatment. Do not use on coarse soils or soils with less than 1.5% organic matter. Heavy rain after application may injure crop. Preharvest interval is 50 days for dry peas. |

MCPB (Thistrol) |

0.5 to 1.5 lb ae/A. Use higher rate during cool weather. Apply when peas have six to twelve nodes, but before flower buds form, and Canada thistle is 4 to 10 inches tall. Canada thistle is only suppressed and usually regrows. Do not feed peas or vines to livestock. Do not apply if temperature is expected to exceed 85°F within the next 24 hours. Do not spray peas under moisture stress. |

Disclosure: Common chemical and trade names are used in this publication for clarity by the reader. Inclusion of a common chemical or trade name does not imply endorsement of that particular product or brand of herbicide and exclusion does not imply non-approval. Recommendations are not meant to replace those provided in the label. Consult the label prior to any application.