Manure Composting for Livestock & Poultry Production

Dealing with manure is a reality for animal agriculture, especially when livestock or poultry are confined for any length of time in pens, corrals, lots or barns. This publication addresses medium-to-large scale composting as a management option for producers.

Last Updated: 04/17by Thomas Bass, Livestock Environment Associate Specialist, MSU Extension; Julia Dafoe, Research Associate, Montana Agricultural Research Station; and Joel Schumacher, Extension Economics Associate Specialist

COMPOSTING IS USUALLY ASSOCIATED WITH

dry manure handling systems, though separated solids from liquid manure handling systems are also compostable. It is important to understand that effective composting is a managed process and the work put into it must be worth the effort.

The decision to compost should make economic sense, or serve as a solution to another management issue. Some important factors in deciding to compost or manage raw manure are compared in Table 1 on page 2. Often, raw manure is the better choice for conventional agricultural applications, while compost may be more useful or acceptable to certain markets outside of agriculture. It is important to understand that composting may represent an entirely new business enterprise for livestock and poultry producers. New opportunities and risks are associated with any new enterprise.

Livestock manure and manure composted with byproducts, such as spent bedding, make excellent fertilizers and soil amendments. Manure and compost contain necessary plant nutrients such as nitrogen, phosphorus and potassium, in addition to a variety of micronutrients. These products may be used alone, or as a compliment to commercial fertilizer applications; in some cases, manure and compost offset the amount of commercial fertilizer purchased by farmers or gardeners. Also, the high organic content of manure and manure compost can help improve soil quality by enhancing water- and nutrient-holding capacity. As Table 1 describes, many factors can play into a producer’s decision to compost.

Figure 1. Windrows near Bozeman.

Composting Basics

Composting is a process in which oxygen-consuming bacteria and fungi feed on the mixed organic wastes in a pile or windrow and convert the waste to compost. Properly managing a compost pile provides optimum conditions for the bacteria and fungi that do the real work of composting. These microorganisms require four things: carbon (C), nitrogen (N), water, and oxygen.

Carbon and nitrogen need to be provided in balance; a C:N ratio of about 30:1 at the beginning of the composting process is desirable. To achieve this, it is important to know the C:N ratios of the composting feedstocks (i.e., carbon materials such as straw, sawdust, animal bedding, etc. added to the manure) and devise a good “recipe” or mixture. Raw manure from most species has C and N within range to compost, while materials such as straw and wood scraps contain mostly carbon and will not compost very well on their own.

TABLE I. Manure vs. Compost: Situational Preferences.

| Situation | Raw Manure | Compost | Notes |

| Use on fields for conventional crop production | X | Raw manure will have higher nitrogen content, but potentially more weed seeds than compost | |

| Use on fields for organic crop production | X | X | Compost has more flexibility for certified organic growers |

| For use in gardens, pots and beds | X | Compost may be more “consumer friendly” | |

| Use in commercial nurseries and tree farms | X | Compost is generally preferred by commercial horticulture | |

| Erosion control and land remediation | X | Compost is often preferred by these markets/users | |

| Value added business opportunity; compost may have enhanced benefits | X | Markets must exist in area for compost; premium price must be acceptable | |

| Neighbors sensitive to raw manure field application | X | Land applied compost will have little to no odor | |

| Need to export manure due to nutrient balance | X | X | Depends on opportunity for use |

| Need to export manure; transportation distance is great, need to reduce bulk | X | Composting reduces overall volume and concentrates phosphorus | |

Use on golf courses and sports fields |

X |

Compost is often preferred by these markets/users because of low odor, and reduced pathogens and weed seeds |

TABLE 2. Range of manure characteristics from livestock species.

Manure Type |

Percent (%) | Ratio | |

| N | H20 | C:N | |

| Beef feedlot 1 | 0.2 - 3.0 | 20 - 80 | 10:1 - 20:1 |

| Swine | 0.3 - 0.5 | 70 - 85 | 15:1 - 21:1 |

| Dairy | 0.3 - 0.6 | 75 - 90 | 8:1 - 30:1 |

| Chicken | 0.8 - 2.5 | 50 - 87 | 4:1 - 18:1 |

| Broiler litter | 1.7 - 6.8 | 22 - 29 | 6:1 - 24:1 |

| Turkey | 1.2 - 1.8 | 50 - 872 | 4:1 - 18:1‡ |

TABLE 3. Carbon content and C:N ratio of bulking materials.

| Material | % N (dry weight) | C:N |

| Corn stalks | 0.6-0.8 | 60-73:1 |

| Straw | 0.3-1.1 (0.7) | 48-150:1 (80:1) |

| Bark, hard woods | 0.1-0.4 (0.24) | 116-436:1 (223:1) |

| Bark, soft woods | 0.04-0.39 (0.14) | 131-1285:1 (496:1) |

| Newsprint | 0.06-0.14 | 398-852:1 |

| Sawdust | 0.06-0.8 | 200-750:1 |

| Wood chips | 0.04-0.23 (0.09) | 212-1313:1 (641:1) |

| Leaves | 0.5-0.13 (0.9) | 40-80:1 (54:1) |

The numbers in parentheses are averages. Compiled and original data: Wortmann, C.S. et. al.

Table 2 provides some ranges of manure characteristics, while Table 3 shows C:N ranges of common carbon sources for composting. Most choose to experiment on-farm to determine the mix that works best for local conditions. On-site experimentation can begin with 75 percent raw manure to 25 percent carbon amendment (chopped straw, wood chips or saw dust, or other crop residue). If the manure is fairly consistent with little bedding material or soil, then additional carbon may need to be added. Conversely, manure that contains a lot of bedding may not require any additional carbon material to properly compost. (Horse manure mixed with bedding material often requires supplemental nitrogen to promote proper composting.) More nitrogen (N) is preserved in the final product when C:N ratios are in the higher end of the recommendation.

Water and oxygen also have to be provided for the microorganisms and are related to each other. If the compost is too wet, the oxygen levels will be too low. In most composting scenarios, best success is attained with a moisture level at about 50 percent. The moisture content can be determined by weighing a sample, drying it and then reweighing, but it can also be estimated from a “squeeze test.” The compost can be squeezed in a fist and should be wet enough to stick together in a ball, yet not so wet as to drip. To achieve this moisture level, irrigating is often necessary and should be done during turning. If the original materials seem dry, then irrigation may also be required at the time the piles or windrows are first built.

The oxygen content in a compost pile should be about five to 20 percent. Some operators purchase hand-held oxygen meters to periodically measure that level, but it is not necessary. A decrease in compost pile temperature after the start of the process is often a sign that there is an inadequate level of oxygen. Turning the pile is commonly used both to mix the ingredients and to add oxygen into the pile. The use of bulking material (a coarse-textured organic waste like wood chips) also aids in initial aeration of a compost pile. Trial and error through turning, and monitoring temperature, can provide the experience to make quality compost. Compost that is too wet is likely to have low oxygen and will not heat up or perform as desired.

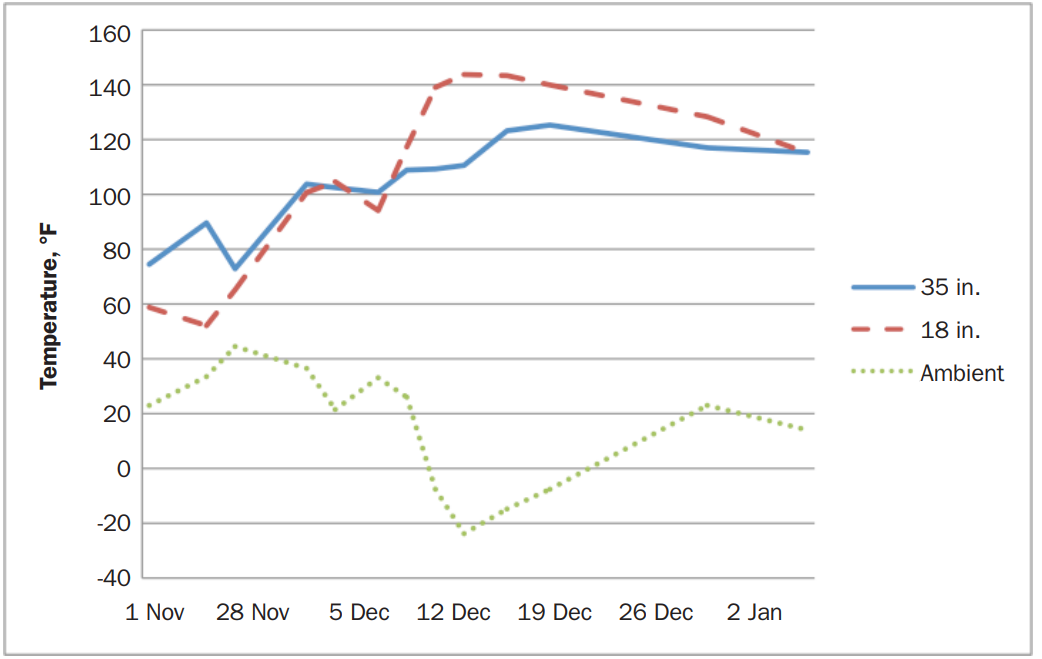

Temperature is an important indicator of how your compost pile is doing, because it is a reflection of the activity of the microorganisms in the pile. When microbes feast, they multiply and give off heat. To monitor temperature a compost thermometer is used; it has a long probe (24 to 36 inches long) and a dial or digital readout on the end. (These can be purchased for $75 to $100 through natural resource and agricultural supply companies.) Thus, measuring temperature is a way to check on the microbes to ensure that they are alive and functioning optimally.

FIGURE 2. Windrow temperatures over a 5-week period.

ECONOMICS OF COMPOSTING

Livestock operations may consider composting as a manure management practice that creates a value-added product, helps meet environmental goals or permit requirements for nutrient balance, or creates a high quality soil amendment for on-farm application. Whatever the reason for composting, understanding the cost and benefits is important. This cost-benefit analysis should be compared to alternate manure management practices.

Costs are also incurred during each step of the composting process. The first step is to clean the raw manure from pens, corrals or other confined areas. This step is likely already undertaken at regular intervals by most operations. The costs of this include labor, equipment (tractor with loader) and fuel expenses. The second step is to pile the manure. Labor, equipment (tractor with loader) and fuel are required for this step. The expense in the first two steps are likely already accounted for because they are the same as managing raw manure.

The third step is to monitor the temperature and oxygen levels in the pile. The costs for monitoring include labor and equipment (temperature gauge and oxygen sensor) expenses. The results of monitoring define the schedule and number of times the compost will be turned (likely four to six times). The costs for this include labor, equipment (tractor with loader or a tractor with a compost turner) and fuel expenses. The final step is delivery to the end user of the compost. For on-farm use, this may involve spreading the compost with a manure spreader. For off-farm markets, this may involve loading compost into a customer’s vehicle, delivering bulk compost or bagging the material for retail sales. The cost for this step varies significantly depending on the end market for the compost.

Case Study Examples

The actual cost of composting was tracked for two different operations in Montana. The first was the 280-goat, Amal- theia Organic Dairy. Amaltheia tracked the time and equipment required to complete each step of their composting operation. Amaltheia utilized a small skid-steer loader to complete most of their composting activities. Amaltheia markets their compost to several different markets. These markets are: 1) Bagged compost for sale to gardeners at retail locations; 2) Bulk sales where the customer transports the compost; 3) Bulk sales where Amaltheia delivers the compost; and 4) On-farm application of the compost as a fertilizer replacement. Figure 3 displays the costs (labor, equipment, fuel and supplies) associated with each marketing option.

The composting process at MSU’s Northern Agricultural Research Station (NARC) was also examined. NARC operates much like a 300-head beef feedlot, in terms of manure production and management issues. NARC utilized a compost turner and a tractor with a loader to complete their composting activities. NARC tracked three marketing options for their compost/manure: 1) On-farm application of raw manure; 2) On-farm application of compost; and 3) Bulk compost sales in large lots, with the customer transporting the compost. Figure 4 displays the costs associated with each marketing option.

The case studies both indicate that composting does increases costs over application of raw manure. The benefits of composting should compensate livestock owners for these additional costs, unless there is an alternative manage- ment objective being met.

FIGURE 3. Small Dairy Case Study: Cost of Compost FIGURE 4. Feed Lot Case Study: Cost of Compost

Cool temperatures (less than 80°F) indicate that the microbes are not thriving (refer to page 3, Water and Oxygen). Temperature should initially be checked every couple of days after building a pile or windrow. A graph of the temperature over time would show a quick rise to about 130 to 160°F within in one to four days and then a gradual decline. Under normal composting conditions, when temperature declines for a week, it is time to turn the pile in order to aerate it. This typically results in mounting temperatures again, if conditions remain optimum. Temperatures in the range of 140 to 160°F, held for 48 to 72 hours, are necessary to sterilize weed seeds and destroy pathogens. Expect four to six turnings prior to curing.

Composting Systems and Siting

Manure can be composted in bunkers, piles or windrows. A bunker or large bin will minimize the area needed to compost, however passive aeration (natural airflow and convection currents) can be inhibited when compost is stacked up against solid sides. A bunker of slatted walls will help provide the natural airflow needed between turnings. A bunker or large bin type system is more feasible for smaller composting endeavors. Other systems such as forced aeration beds or rotary drums do exist, though they are not covered in this publication.

Piles and windrows are more common and easiest to manage for medium-to-large scale composting. Piles take up the most space for the amount of material produced. A pile four to five feet high will likely have a base diameter of eight to 10 feet. A windrow is essentially a long pile, but takes advantage of its mass to better maintain temperature and shape. A windrow four to five feet high will also have a footprint of eight to 10 feet wide; it may begin as a single pile, with new batches of manure and carbon material stacked up against previously added material.

The composting pad should be level and situated on higher ground to limit water running into the area. The area should have good all-season access and should not be near creeks, wetlands, wells or shallow groundwater (100 feet is a reasonable setback). Composting can generally be done on the existing soil; however, some situations (such as persistent mud or shallow groundwater) may require an engineered surface.

Equipment, Turning and Finishing

Medium-scale composting can be managed with a small front-end loader; however, for larger agricultural compost operations, a compost windrow turning machine is recommended. The front-end loader is used to move materials and build the compost piles or rows. For most farm/ranch composting operations, a front- end loader is also used to move and turn the pile.

As previously described, turning should be based on temperatures. However, it can be expected to turn about once a week, for up to six weeks. With a front-end loader, simply push the top of the pile or row over and rebuild to similar dimensions off to the side. By moving the row or pile back and forth in such a fashion, the materials can be re-mixed and aerated (oxygenated).

A compost turner will either turn the windrow in place or slightly off to the side. It automatically, mixes, provides additional particle size reduction, aerates and rebuilds the pile. Units are commonly run off of a tractor’s pwer take-off (PTO), but may also have their own power source for some functions. Such machines may run between $20,000 for a used unit, and upwards of $60,000 for some new units.

FIGURE 5. Tractor with compost turner near Havre.

In Montana, you will likely need to add water if composting between mid-July and mid-September, or if using stockpiled manure. During or just prior to turning is the most effective time to irrigate; refer to the squeeze test for informal estimates of moisture needs. The final number of turns and additional processing will be determined by the end-use market. For example, home and garden markets prefer a very finished product that could involve more than six turnings and a screening to provide a very consistent quality product. Agricultural use or remediation projects would not require the same level of finishing.

Once the bacteria and fungi no longer respond to aeration, i.e. the piles do not heat up after turning, the active phase is over and the curing phase can begin.

During the curing phase the compost is not turned and the active microbial population decreases. The pile or windrow will stabilize to near ambient temperatures. A general rule of thumb is the compost cures for the same amount of time it was active. For example, if the pile was active for six weeks, then it cures for six weeks.

Compost Markets and Uses

Compost opens up new markets to the livestock and poultry producer. Compost is generally preferred

in horticultural and silvicultural operations, for the general consumer or homeowner and for applications such as construction site erosion control and land remediation. Before a producer decides to compost, they should consider the costs and benefits of composting.

FIGURE 6. Bagged premium compost.

If a producer simply needs to eliminate manure, they may try to advertise it for pick-up by the end user. However some buyers may prefer or need delivery.

Selling in bulk is often the easiest compost market to access. If a local garden market is present, then bagging in 25 to 40 pound bags may bring in more revenue; however, the extra cost of labor, bags and marketing must be considered.

Compost quality is of higher concern for general consumer-oriented markets. The material must be free of trash, of fairly homogenous particle size, and without residual manure odor. Montana is currently without a commercial compost standard. A laboratory analysis is key to selling a quality product. Permitted animal feeding operations are required to provide the recipient of any manure product from the operation with a current analysis. The Minnesota Department of Agriculture maintains a list of manure and compost testing laboratories, see Resources and References on the following page.

When compost is properly monitored and manufactured, benchmark temperatures that sterilize weed seeds and kill pathogens will be reached. This also enhances quality and protection from these threats to the end user. Other factors in the composting process also contribute to the destruction of weed and other plant seeds. Most herbicides and many pesticides are NOT destroyed and can have varying degrees of residual effect after composting. This is a very important issue since those chemicals can have a negative impact on end users.

Broad leaf herbicides are perhaps the most significant adulterant to compost, as they will kill or stunt the growth of plants intended to grow in the compost or compost-conditioned soil. Such herbicides applied to hay or forage crops will first persist through the animal’s digestive tract and into the compost. The use of herbicide immediately around the composting location can adulterate the material as well. If compost is used back on a conventional agricultural application, this may not pose a problem; but, it is definitely an issue for consumer-based markets and use.

Summary

Composting of manure is a feasible practice for Montana animal feeding operations that may provide additional income or address other manure management concerns. On-site trial and error is necessary to establish composting at any location;

however, the guidelines in this bulletin should provide a basis for getting started. For more information, contact your local MSU Extension office (www.msuextension.org) or the Montana Agricultural Experiment Station at Havre:

Resources and References

Davis, Jessica G. portions of the section, "Composting Basics" (page 1) include paraphrased original content from Dr. Davis, Colorado State University Extension

Field Guide to On-Farm Composting. 1999. Plant and Life Sciences Publishing. Ithaca, New York. 128p. http://palspublishing.cals.cornell.edu/nra_order.taf?_function=detail&pr_booknum=nraes-114

Minnesota Department of Agriculture. Certified Manure Testing Labs. http://www2.mda.state.mn.us/webapp/lis/manurelabs.jsp

Wortmann, C.S. et. al. Composting Manure and Other Organic Residue, NebGuide G1315, 1997 (Revised April 2006).

Acknowlegements

Portions of this project were funded by a grant from the Western Sustainable Agriculture Research and Education Program, http://wsare.usu.edu.