Integrated Weed Management in Lentils

As market demand rises for pulse crops and lentil acreage expands, integrated management plans must be modified to prevent and control weeds in this new cropping system. This Montguide reviews approaches to develop integrated programs to reduce the spread and impact of weeds in lentils.

Last Updated: 03/12by Fabian Menalled, Extension Cropland Weed Specialist

Managing Weeds in Lentils

In recent years there has been increased interest in diversifying Montana’s cropping systems through the inclusion of pulse crops such as peas, dry beans, chickpeas, and lentils. Pulse production provides several agronomic advantages and opportunities to increase profit margins. Besides tolerating drought conditions, cool temperatures, and a wide variety of soil types, leguminous pulse crops can also help fix nitrogen in the soil. However, growers should be aware of the challenges and opportunities of managing weeds in these crops.

Weed management in lentils is of particular importance as this crop is generally considered to be a poor competitor due to its slow establishment and limited vegetative growth. Yield loss from competition with weeds can range as high as 80 percent. Lentil’s low competitive ability is compounded when growing season temperatures are low or when moisture is scarce. Growers considering incorporating lentils into their rotation should develop an Integrated Weed Management plan that considers the entire crop lifecycle from pre-planting to after-harvest. In doing so, they need to take advantage of cultural, physical, and chemical practices to reduce the spread and impact of weeds invading lentil fields. In Montana, difficult to manage weeds in lentils include catchweed bedstraw, Canada thistle, Russian thistle, kochia, common lambsquarters, cow cockle, shepherds purse, henbit, Mayweed chamomile, wild buckwheat, prickly lettuce and dandelion. Of these, Canada thistle and catchweed bedstraw are particularly difficult to control and producers should avoid fields with a history of these species.

FIGURE 1. Lentil plant characteristics; 1) flowering and fruiting branch, and 2) seeds.

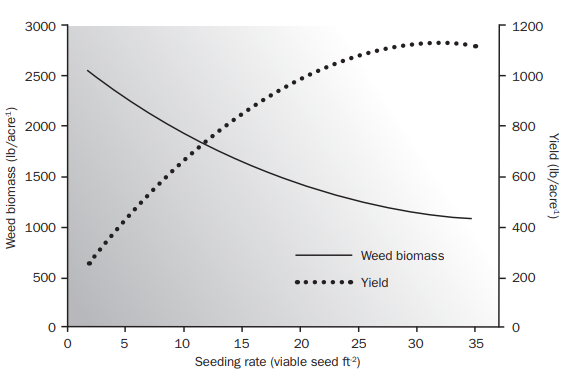

Cultural practices to decrease weed pressure in lentil crops include prevention, seedbed preparation, variety selection, proper sowing and crop establishment, insect and disease management, nutrition management, and irrigation scheduling. For example, Baird and collaborators (2009) observed that increasing the seeding density of lentils translated into increased yield and decreased weed biomass (Figure 2, page 2). However, while cultural practices are at the backbone of an integrated weed management plan, they alone may not be enough to secure adequate weed control in lentil fields. More information on cultural considerations and variety selection can be found in the Montguide, Growing Lentils in Montana (MT199615AG)

Mechanical weed control practices in lentils, such as harrowing or rotary hoeing fields after emergence, represent a viable alternative for organic producers. Producers should be aware that mechanical weed control practices should be applied with caution due to the high sensitivity of lentil shoots and roots to damage. If harrowing or hoeing is planned, be sure to increase seeding rates because mechanical damage may reduce stands. Also, producers should minimize the risk of soil erosion due to excessive reliance on tillage.

FIGURE 2. Effect of lentil seeding rate on weed biomass and yield. Adapted from Baird and collaborators (2009).

Crop rotation is one of the most powerful tools to manage pest problems. It is very important to carefully consider the crop rotation history prior to growing lentils as this crop is very sensitive to many herbicides used in small-grain production. The high persistence SU- herbicides commonly used in small grain crops such as Ally (metsulfuron), Glean (chlorsulfuron), and Finesse (chlorsulfuron) can damage subsequent annual legumes, including lentils. Due to their persistence, it may be necessary to wait up to four years before seeding lentils, depending on the product, application rate, and weather conditions.

The persistence of herbicides in the soil depends on many factors including soil pH, moisture, temperature, soil texture, and soil organic matter. Understanding the risk of crop injury due to soil applied herbicides is particularly important in areas with dry climate and prolonged winters, like Montana, where herbicides generally degrade slowly (Table 1, page 3).

Chemical weed control can help reduced-till or no-till lentil producers manage weeds. Research and experience has shown that herbicides are most effective when used as part of an IWM program. The applicability and success of herbicides in lentil fields depends on the cropping system, land preparation methods, soil conditions, and weed problems. For example, Sencor (metribuzin) applied at recommended rates provides effective weed control, but it can cause crop damage in stressful conditions of cold weather, low fertility, disease, or insect damage. Also, although Pursuit (imazethapyr) can be used to manage broadleaf weeds in no-till or minimum tillage systems, cold and wet conditions occurring within a week of application can severely damage the crop.

While information on commonly used herbicides used to manage weeds in lentils is provided below, producers should carefully read and follow product labels prior to using any herbicide.

What is Integrated Weed Management?

Integrated weed management (IWM) combines the use of biological, cultural, mechanical, and chemical practices to manage weeds, so that reliance on any one weed management technique is reduced. The main goals of an IWM program are to 1) use preventive tools to maintain weed density at a level that does not harm the crop, 2) prevent shifts toward more difficult to control weeds, and 3) develop agricultural systems that maintain or improve crop productivity, farm revenues, and environmental quality. Designing a successful IWM program requires understand- ing the different biological and ecological factors that influence the short-, mid-, and long-term dynamics of weeds in agricultural settings.

More information on IWM can be found in Montguides Integrated Strategies for Managing Agricultural Weeds: Making Cropping Systems Less Susceptible to Weed Colonization and Establishment (MT200601AG) and Weed Seedbank Dynamics & Integrated Management of Agricultural Weeds (MT200808AG).

TABLE 1. Lentil rotation interval for herbicides commonly used in Montana.

| Product | Common name | Minimum rotational interval | Notes |

| Ally | metsulfuron | 34 months | Rotation interval for soil pH of 6.9 to 7.9. Shorter intervals for lower pH values. |

| Amber | triasulfuron | 4 months | Lentils may be planted after the completion of a successful field bioassay. |

| Assert | imazamethabenz | 40 months | Lentils may be planted after the completion of a successful field bioassay. |

| Beyond | imazamox | 18 months | Apply only on Clearfield crops. Spray drift may injure non-Clearfield lentils. |

| Glean | chlorsulfuron | 36 months | Conduct a field bioassay if soil pH is above 6.5. Similar recommenda- tions for Finesse (chlorsulfuron + metsulfuron) |

| Huskie | pyrasulfotole and bromoxynil | 18 months | Huskie herbicide breakdown in the soil is due mainly to microbial action. Under cold and dry conditions, degradation may be slowed. |

| Peak | prosulfuron | 22 months | Conduct a field bioassay if soil pH is above 7.8. |

Stinger |

clopyralid |

18 months |

In Montana where soils commonly have less than 2 percent organic matter (OM) and there was less than 15" of precipitation within the year following herbicide application, it is necessary to perform a field bioassay. Similar recommendations for Curtail (clopyralid and 2,4-D). |

| Maverick | sulfosulfuron | 22 months | If soil pH is above 7.5, perform a field bioassay. |

Assure II (quizalofop). 5 to 12 ounces/acre. Apply postemergence (POST) to manage annual and perennial grasses. Apply with crop oil concentrate (COC) or nonionic surfactant (NIS). Application intervals should be greater than seven days apart to allow re-growth. Do not apply within 60 days of harvest. Consult label for crop rotation restrictions.

Dual Magnum (7.62 EC)/generic S-metolachlor products. 1 to 2 pints/acre. Apply Preplant Incorporated (PPI) or Preemergence (PRE). For annual grass and some broadleaf weed control. Does not control emerged weeds. Incorporation improves control. Refer to label for specific rate information regarding soil texture and organic matter. Use low rates on coarse soils with less than three percent organic matter (OM) and higher rates on fine soils with over three percent OM.

Far-Go (triallate). 1.5 quarts/acre. PPI. Mostly used to manage wild oats. Apply up to three weeks before seeding or after seeding before sprouts are 0.25” long. Apply prior to wild oat germination. A two-pass incorporation is recommended. Do not rotate to crops other than winter wheat, spring wheat and durum, triticale, barley, peas, lentils, and sugar beets for 12 months after a Far-Go application. In Montana, do not use Far-Go on fields to be seeded to hard red spring wheat with press drills if the field is or will be irrigated in the current growing season.

Outlook/generic dimethenamid-p. 10 to 16 ounces/ acre. Apply pre-plant surface or PRE to lentils. Good to excellent control of several annual grasses. Fair to good control of certain annual broadleaf weeds such as pigweed, waterhemp, or black nightshade. Adjust rate for soil type and OM. Consult your seed dealer for restrictions on specific varieties to avoid potential injury due to sensitivity. Emerged weeds are not controlled. May occasionally result in temporary spotting or browning of crop leaves. Lentils may be harvested 70 days after application. Refer to label for tank-mix options.

Paraquat products. Available in several brand name products including Gramoxone Inteon, Gramoxone Max, Firestorm, Parazone 3SL, and others. Follow specific label directions for product used. HARVEST AID: apply when at least 80 percent of pods are yellowing and mostly ripe. Follow handling precautions as Paraquat is toxic when ingested. Restricted Use Pesticide.

Timing is EverythingTo maximize the effectiveness of any weed man- agement practice and avoid yield reduction, it is important to target the proper crop growth stage. Research conducted at the University of Saskatch- ewan, Canada, showed that weed control in lentils should start by the five- to six-node stage, and lentil fields should continue weed-free until the ten- to eleven-node stage. While the environmental condi- tions under which this study took place differ from the ones we experience in Montana, these results can help lentil growers time their weed management practice.

Poast (sethoxydim). 2.5 pints/acre, do not exceed 4.0 pints/acre per season. POST: Annual grasses (2-4 inches). Requires COC additive. Apply to actively growing grasses. Do not graze or hay vines for livestock feed. Allow 50 days from application before harvest.

Prowl, Prowl H2O, Pendimax, and other pendimethalin products. Formulation and use may vary. Follow directions for product used. 1.5 to 3 pints/ acre Prowl H2O. PPI. Fall applications. Excellent control of several annual grasses and fair control of small-seeded annual broadleaf weeds such as pigweed and lambsquarters. Poor or no control of mustard, nightshade, smartweed, or large-seeded annual broadleaf weeds. One inch rainfall or mechanical incorporation required prior to planting. Use lower rate on coarse soils and higher rate on fine-textured soils.

Roundup/generic glyphosate. Check labels as glyphosate is available in several products having different formulations and different amounts (pounds) of acid equivalent (ae) and active ingredient (ai). Consult labels for rates. BURNDOWN: Weeds should be actively growing. Avoid tillage for one day after treating annual weeds and three to seven days for perennials. Some products contain adequate surfactant; others require NIS and ammonium sulfate (AMS) additive. Use caution to avoid droplet drift to non- target crops. SPOT TREATMENT: Crop will be killed in treated areas. Allow a 14 day pre-harvest interval for spot treatment. PREHARVEST: refer to specific glyphosate product label for rates and precautions.

Sencor DF 75 (metribuzin). A pre or post herbicide used to control several broadleaf weeds including mustards, pigweed, mayweed, and common lambsquarters. Apply 0.25 to 0.5 lbs/acre. Temporary chlorosis of the crop may occur. There is a risk of crop injury if lentils are under stress conditions caused by cool weather, low fertility, disease, or insect damage

Treflan/generic trifluralin. Treflan HFP should be applied at 1-2 pints/acre. PPI. Follow directions for product used as application rates and label instructions may differ. Tolerance is marginal and crop injury may occur. Rate should be adjusted depending on soil and rainfall or irrigation. Consult label for additional information. In Montana uses of some Treflan formulations may be limited to those described in supplemental labeling.

Preventing herbicide resistanceHerbicide resistance is the innate ability of a weed biotype to survive and reproduce after treatment with an herbicide dose that would normally be lethal. In Montana herbicide resistant biotypes of wild oat, Persian darnel, green foxtail, kochia, and Russian thistle have been found.

To reduce the risk of selecting for herbicide resistant biotypes, producers should rotate among herbicides with different modes of action applied either as tank mixes, premix formulations, or sequential applications. Also, producers should rotate management practices, such as the incorpo- ration of timely cultivation. Finally, crop rotation is an excellent tool to reduce the selective pressure on herbicide resistant weeds. More information on herbicide resistance can be found in the Montguide, Preventing and Managing Herbicide-resistant Weeds in Montana (MT200506AG).

Reducing the risk of herbicide injury in lentil crops

Herbicides are valuable tools: they help to control weeds and, if they are residual, can provide season-long control. However, miscalculations in their use can cause crop injury or failure to control weeds. Montana producers know that losing a crop due to lack of rain is an unfortunate but inevitable experience. Losing a crop because of herbicide injury could be as bad as a weather calamity, but it can be prevented. Minimizing the risk of herbicide crop injury is a necessary step for diversifying dryland cropping systems in Montana to include broadleaf crops such as pea, lentil, canola and sunflower.

To minimize the risk of herbicide-injured crops, we need to understand how herbicides function and the several factors that affect their activity. For example, the soils of Montana are unique in that they have lower organic matter and higher pH than is typically encountered outside this region. Also, many times Montana’s soils are different than those where herbicide residue studies have been conducted and upon which current recommendations are based.

For the last 3 years, researchers and graduate students at Montana State University have been evaluating the potential damage that herbicides could cause in crops. To determine the best way to maximize the benefits of herbicides while avoiding crop injury we have assessed carryover effects on different crops and soil types across Montana. This information is available at the Cropland Weed Management website, http://www.ipm.montana.edu/CropWeeds - visit the Prevent and Diagnose herbicide Injury link.

More information on approaches to reduce the risk of crop injury due to herbicides be found in the Montguide, Getting the Most from Soil-Applied Herbicides (MT200405AG).

Managing weeds in herbicide-tolerant lentils

Lentil producers can take advantage of the Clearfield system to manage tough weeds. The Clearfield system combines herbicide-tolerant (non-GMO) lentil varieties with Beyond herbicide (imazamox). Beyond is a broad- spectrum post-emergence herbicide that provides post- emergence and in-season residual weed control of several annual broadleaf weeds such as chickweed, shepherd's- purse, field pennycress, common lambsquarters, pigweed and wild buckwheat. It also provides control of several grasses including jointed goatgrass, feral rye, downy brome, Japanese brome, cheat, Italian ryegrass, wild oats and volunteer cereals.

Preventing the selection and spread of herbicide- resistant weed biotypes is a challenge to the Clearfield technology. Beyond inhibits the activity of the acetolactate synthase (ALS) enzyme, the first step in the biosynthesis of the branched chain amino acids valine, leucine and isoleucine. The lack of these amino acids restricts the building of proteins and results in the slow death of treated plants. ALS inhibiting herbicides have been used in crop production since the 1980's. Unfortunately, the likelihood of selecting resistant weed biotypes with the continuous use of this class of herbicides is very high.

TABLE 2. Glyphosate and paraquat differ in the way the work on plants and their use as pre-harvest aid.

| Glyphosate | Paraquat |

| Winter annual and perennial weed control | Desiccates crops and weeds |

| Slow acting (weeks) | Fact acting (days) |

| Systemic, non-selective | Contact, non-selective |

| Affects actively growing tis- sue of plants | Affects all green tissue of plants |

| Adversely affects seed germination | Does not affect seed germination |

| Less expensive | More expensive |

| Apply at less than 30% seed moisture | Apply when majority of seed shows color turn |

How to conduct a field bioassay

Field bioassays allow producers to evaluate the risk of crop damage due to herbicide carryover. Using typical management practices (tillage, seed- ing depth, timing for the particular crop, etc.) plant several strips of the desired crop variety across the field which has been previously treated with the suspected herbicide as well as areas that have not been treated with the herbicide. Plant the strips perpendicular to the direction the herbicide was ap- plied. Place these strips to capture field heteroge- neity due to differences in soil pH, texture, organic matter, and drainage. Using the untreated areas as a control, check the crop for visible symptoms of injury, stand reduction, and/or yield reduction. If no herbicide injury symptoms or yield reduction is visible, the field can be seeded with this crop the next growing season after the bioassay. However, if visible herbicide injury symptoms or yield reduction occur, this crop must not be seeded, and the bioas- say must be repeated the next growing season.

Weed management at harvest

Many times after a cool and wet summer, weeds keep on growing and lentils continue flowering and setting pods. These conditions mechanically impair the harvest of the crop, and herbicides can aid lentil growers in harvesting crops. Some of the advantages of a pre-harvest herbicide application include facilitating direct combining of standing crops, managing in-crop weed escapes, reducing dockage, and controlling perennial weeds in subsequent crops.

Lentil growers must carefully ponder the management goal, the weeds present, and the crop seed maturity stage prior to applying a preharvest herbicide as these variables will affect the herbicide choice. There are two common choices for an in-crop, pre-harvest herbicide: Roundup (or other generic glyphosate) and paraquat. A pre-harvest application of glyphosate provides adequate weed control including winter annual and perennial weeds, but the crop will be slow to dry down. Glyphosate should not be applied to lentils grown for seed production as germination and possibly vigor problems may occur in the spring. Paraquat is a true desiccant herbicide that should be used when the main goal is to desiccate the crop (Table 2). Remember that herbicide use will not speed up crop seed maturity.

Glossary

Ammonium sulfate (AMS) is an additive recommend by many herbicide labels. AMS often improves weed control, especially when mixed with hard water.

Crop oil concentrate (COC) is comprised of a non- phytotoxic (not causing injury) mineral and/or vegetable oil and can contain up to 20 percent surfactant. The principal function of the COC is to aid in moving the herbicide across the leaf cuticle and reduce the surface tension of the spray droplets. Crop oils are also effective at increasing spray retention on leaf surfaces and reducing drying times, allowing more time for the herbicide to penetrate the leaf.

Genetically modified organism (GMO) or genetically engineered organism (GEO) is an organism whose genetic material has been modified through the use of genetic engineering techniques. Genetic engineering combines DNA molecules from different sources to create a new set of genes. This new molecule is then transferred into an organism, giving it modified or novel genes.

Nonionic surfactants (NIS) are specialized additives formulated to improve the performance of herbicides in spray solution. The function of the NIS is to spread the spray droplet evenly over the leaf surface, help it to adhere to the leaf, and increase penetration of the herbicide within the spray droplet into the waxy cuticle that covers the leaf surface.

Sulfonylurea (SU)-herbicides are a family of herbicides discovered in 1975 and widely used in Montana. SU herbicides work by inhibiting a key enzyme – acetolactate synthase – which is unique to plants (not present in humans, animals, insects, birds or fish) and is needed for plant growth. Examples of SU herbicides include Maverick (sulfosulfuron), Glean, Finesse and Ally.

Additional readings and material

Alberta Pulse Growers. http://www.pulse.ab.ca Baird J.M., S.J. Shirtliffe, and F.L. Walley. 2009. Optimal seeding rate for organic production of lentil in the northern Great Plains. Canadian Journal of Plant Science 89: 1089-1097.

Cash, D., R. Lockerman, H. Bowman, and L. Welty. 1996. Growing lentils in Montana. Montguide MT199615AG. http://msuextension.org/publications/AgandNaturalResources/MT199615AG.pdf

Derksen, D.A., R.L. Anderson, R.E. Blackshaw, and B. Maxwell. 2002. Weed dynamics and management strategies for cropping systems in the northern Great Plains. Agronomy Journal 94: 174-185.

Miller P.R., B.G. McConkey, G.W. Clayton, S.A. Brandt, J.A. Staricka, A.M. Johnston, G.P. Lafond GP, B.G. Schatz, D.D. Baltensperger, and K.E. Neil. 2002. Pulse crop adaptation in the northern Great Plains. Agronomy Journal 94: 261-272.

Northern Pulse Growers Association. http://www.northernpulse.com/

University of Saskatchewan Pulse Crop Research Group. http://www.pulse.usask.ca

Disclosure: Common chemical and trade names are used in this publication for clarity by the reader. Inclusion of a common chemical or trade name does not imply endorsement of that particular product or brand of herbicide and exclusion does not imply non-approval. Recommendations are not meant to replace those provided in the label. Consult the label prior to any application.