Calibrating Pesticide Application Equipment

Improperly calibrated pesticide equipment may cause either too little or too much pesticide to be applied. This can be averted with an organized approach to calibration that includes ample time, the correct tools, and a fundamental understanding of calibration.

Last Updated: 08/22by Cecil Tharp, Pesticide Education Specialist, MSU Department of Animal and Range Sciences

IMPROPERLY CALIBRATED PESTICIDE EQUIPMENT

may cause either too little or too much pesticide to be applied. Excess pesticide inadvertently causes phytotoxicity and increased contamination of surface and groundwater, while a deficient pesticide application wastes time and money with little benefit. Either scenario can be averted with an organized approach to calibration that includes ample time, the correct tools, and a fundamental understanding of calibration. This publication will aid applicators in implementing a well-organized approach to the calibration of their pesticide application equipment.

An applicator may assume that properly calibrated equipment stored in the fall will be properly calibrated the next season. This error can lead to damaged or plugged nozzles. Replacing nozzles or calibrating while in a field situation can be frustrating and dangerous. Calibration should occur at least once every

year immediately prior to pesticide applications. You will need a stopwatch, measuring tape, source of fresh water, measuring container, pencil, and paper.

Pre-Calibration Checklist

Immediately prior to calibration give your equipment a thorough inspection. Check pumps, lines, and fittings for leaks while assessing entire sprayer for wear, severe rust, or breakage. It is also important to understand your field speed, nozzle flow rate, desired pressure, and how to assess spray coverage.

1. Know your field speed. Your speed of application is critical when calibrating your sprayer. Ideal speeds generally are a balance between safety and maximizing ground covered. Safety can be a factor when traveling too fast over uneven terrain or obstacles. If you do not have a speedometer, you may mark a 300 foot course and drive at a normal spraying speed (tank ½ full) while timing. Repeat this 2-3 times and calculate average time. Convert to miles per hour (MPH) using this formula:

MILES PER HOUR = Distance (feet) x 60 / Time (seconds) x 88

2. Selecting Nozzle Flow Rate. The selection of the appropriate nozzles can be one of the most critical steps to any calibration process. Remember to purchase and use only nozzles which are correct for your application. The recommended sprayer output in gallons per acre (GPA) that your sprayer should be applying can be obtained from your pesticide product label. You can use this to attain your nozzle flow rate (gallons per minute) with the 5940 equation.

Use the 5940 equation when determining nozzle flow rate. The 5940 equation makes it easy to find desired nozzles for a recommended GPA. Use your product label recommendation in the following equation:

GALLONS PER MINUTE (flow rate of nozzles) = GPA x MPH x W / 5940

GPA = Sprayer Output (Gallons per acre); MPH = Sprayer speed (Miles per hour); W = Nozzle spacing in inches

This will tell you the flow rate for each nozzle on your sprayer. Use this as a guide when purchasing nozzles. Fine tune your nozzle flow rate by making slight adjustments to spray pressure.

3. Spray Pressure. Recommended spray pressure varies by product, so read the label carefully. Increasing pressure raises the flow rate while lower pressures decreases flow rate. To double flow rate you must increase your pressure by four times.

Droplet size can also be controlled by pressure. Less than 30 pounds per square inch (PSI) of pressure is often needed for low drift nozzles due to the much larger droplets produced. High pressures present greater risks of drift due to smaller droplet size. Certain nozzles including the ‘Extended Range (XR) Flat Fan nozzles’ can be used in a wide range of pressures (15-60 PSI) thus minimizing drift, while many of the standard fan nozzles can be used in only 30-60 PSI. The newer ‘air induction’ nozzles create larger droplets which minimize drift under higher pressures (40-100 PSI). Pressure should never be altered to make large changes in sprayer output. However it can be useful in making minor adjustments.

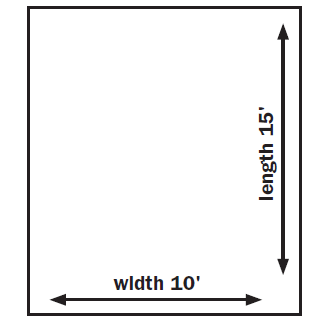

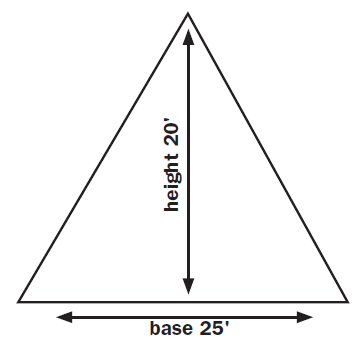

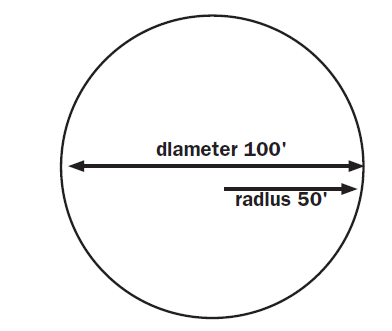

4. Assessing Spray Coverage (Area). To calibrate your equipment or to assess the amount of pesticide needed for a routine spray you will need to determine area. Formulas may be used to determine the area of a rectangle, triangle, or circle. (Figures 1–3.)

Converting to Acres. It can often be desirable to convert area (sq. ft) to acres. This can be accomplished with this formula:

AREA IN ACRES = Area in square feet / 43,560 feet

For example if you are covering 3,000 square feet this can be easily converted to acres:

Area in Acres = 3,000 ÷ 43,560 = 0.0688 Acres

Testing Uniformity of Nozzles

Accurate calibration is a combination of assessing uniform nozzle flow, determining the output rate of your sprayer, and properly mixing your tank. You should always start off by checking all nozzles on spray booms for uniformity.

Nozzles may be worn or damaged, preventing uniform spray coverage. All nozzles across a boom need to be applying the same amount of liquid within a certain error range (usually 10 percent on either side of average). Clean and/or replace any nozzles that fall outside of the error range. When assessing nozzle uniformity follow these steps:

- Collect water from each nozzle for 1 minute. Measure volume.

- Determine average nozzle output.

- Determine the acceptable error range (usually within 10 percent).

- Replace or clean nozzles outside of range and re-test.

|

Example: You have a 5 nozzle boom and have collected water from each nozzle for 1 minute. You note the following outputs.

Nozzle = 1 2 3 4 5

Ounces = 30 29 30 24 50

Total = 143 ounces

Average Nozzle Output = 143 ÷ 5 = 28.6 oz.

Find your 10 percent range: 28.6 x 0.10 = 2.86 oz. to add and subtract from the average. Your range is 25.74 to 31.46 ounces.

|

Calibration of Output (GPA)

If you have determined that your sprayer has uniform nozzle flow rates, then you may determine your actual sprayer output (GPA). Your target output is determined on the pesticide product label. By following the pre-calibration checklist, an applicator should have the appropriate nozzles, pressure, and speed to attain this. The GPA of your sprayer must be assessed while taking into account pressure, nozzle flow rate, and speed in an actual spray setting.

BOOM OR BROADJET SPRAYERS

The longhand method of calibration enables the assessment of output for backpack sprayers, hand gun, boom, and broadjet applications. Be sure that you have verified uniformity of your nozzles prior to assessing output of your boom sprayer. Follow these steps to assess output:

- Establish Spray Strip Dimensions: Nozzle spacing (feet) x Test Strip Distance (example: Nozzle spacing is 3 feet and your test strip is 200 ft long).

- Convert to area: Length x Width = Area of Rectangle (example: 3 ft x 200 ft = 600 square feet).

- Convert to acres: Square feet in test strip ÷ 43,560 square feet = Area (example: 600 ÷ 43,560 = 0.0137 Acres).

- Spray the test strip while measuring time (example: 27 seconds to spray the 0.0137 acre test strip).

- Collect and measure liquid from 1 nozzle (example: in 27 seconds collected 1.1 gallon from 1 nozzle or 1 broadjet).

- Determine GPA: Gallons applied to test strip ÷ Test Strip Acres = GPA (example: 1.1 gallon ÷ 0.0137 = 80.29 GPA).

BACKPACK SPRAYERS

Backpack sprayers also need to be calibrated annually. Follow these steps to calibrate output of your backpack sprayers.

- Establish spray strip dimensions (example: flag out a 15 ft x 15 ft section).

- Convert to area: Length x Width = Area of Rectangle (example: 15 ft x 15 ft = 225 square feet).

- Convert to acres: 225 square feet in test strip ÷ 43,560 square feet = Area (example: 225 ÷ 43,560 = 0.00516 Acres).

- Run the test strip spraying with gentle 180° arc until saturation (but not dripping) while measuring time. Be sure to use constant pressure and speed. Repeat 3 times (example: 40 seconds to cover 225 square feet).

- Collect and measure liquid (example: in 40 seconds collected .10 gallons from nozzle).

- Determine GPA. Gallons applied to test strip ÷ Test Strip Acres = GPA (example: .10 gallon ÷ 0.00516 = 19.38 GPA).

DROP OR ROTARY SPREADERS

Most granular products recommend an output per 1000 square feet. A spreader manual often will give precise instructions on how to achieve these rates. To ensure accuracy an applicator should calibrate annually due to the possibility of worn or damaged parts.

- Mark out a 100 square foot area, preferably over an area that can be cleaned easily (concrete) or lay out a tarp in order to collect the product after calibrating.

- Adjust the spreader to the settings recommended by the spreader applicator manual according to the rates specified on the product label (example: 100 pounds recommended per 1,000 square feet; setting 3).

- Place product in the hopper to more than cover the 100 square foot area. Remember to note weight of product you added to hopper.

- Convert to 100 square feet: 100 lb per 1,000 sq ft÷ 10 = 10 pounds

- Add 50 percent more: ½ x 10 = 5 + 10 = 15 pounds Add 15 pounds to hopper.

- Apply granules to the 100 square foot area walking the same speed at which you plan to use during application.

- Weigh the amount of product left in the hopper and subtract this from the total initial weight (example: 15 pounds initially – 5 pounds left in hopper = 10 pounds added to 100 square feet).

- Multiply by 10 to obtain your output per 1,000 square feet (example: 10 lbs x 10 = 100 pounds per 1,000 square feet).

CONVERSIONS

| Multiply: | By: | To get: |

| Acres | 43,560 | Square feet |

| Cups | 8 | Ounces |

| Gallons | 128 | Ounces |

| Grams | .001 | Kilograms |

| Grams | .035 | Ounces |

| Hectacres | 2.47 | Acres |

| Kilograms | 2.205 | Pounds |

| Liters | .264 | Gallons |

| Meters | 3.28 | Feet |

| Miles/Hour | 88 | Feet/Minute |

| Ounces | 2 | Tablespoons |

| Pints | .125 | Gallons |

| Pints | 16 | Liquid (oz) |

| Pounds | 16 | Ounces |

| Pounds | 453.6 | Grams |

| Quarts | 32 | Ounces |

| Tablespoons | 0.5 | Ounces |

Proper Tank Mixing

Proper tank mixing takes place once you understand your sprayer’s output, the number of acres you wish to spray, and product rate, which is expressed on the label.

DETERMINE AREA YOU CAN EXPECT TO COVER

To determine how much product or solution to add to the tank, you must understand how much area your spray tank can cover. If the tank can not hold enough solution to cover your intended application, it will be necessary to have two or more separate applications. To determine the area you can expect to cover follow this formula.

SPRAYABLE ACRES = Gallons in Tank / Gallons per Acre (GPA)

For example, if your sprayer was calibrated at 30 GPA and your spray tank holds 500 gallons you could spray 16.6 acres (500 ÷ 30 = 16.6 acres).

DETERMINE AMOUNT OF SOLUTION TO MIX

When determining the amount of spray mixture needed in a spray tank simply follow this formula:

SPRAY MIX NEEDED = GPA x sprayed acres

If your sprayer was calibrated at 30 GPA and you needed to spray 15 acres you would need 450 gallons of spray mixture (30 x 15 = 450 gallons).

DETERMINE AMOUNT OF PRODUCT TO ADD TO TANK

An applicator should read the product label to determine the amount of pesticide product to deliver over a given area. This formula will convert this recommendation to the amount of pesticide product to add to your tank.

PRODUCT TO ADD = Acres to spray x product rate

For example, if you are spraying 15 acres and your product rate is 4 oz per acre you would need to add 60 ounces to your spray tank (15 x 4 = 60 ounces).

Winterizing your Spray Equipment

Spray equipment should be winterized prior to storage. This can save time and money in the long run. Always remember to drain your system and pumps prior to running antifreeze into your pumps.

Acknowledgements

I would like to thank Ruth O’Neill (MSU Research Associate), Dave Brink (MSU Mineral County Extension Agent), and Marko Manoukian (MSU Phillips County Extension Agent) for their insight in creating this MontGuide.

For Further Information

Additional resources are available online at http://www.pesticides.montana.edu/. You may also contact your local MSU Extension Office or the MSU Pesticide Education Program:

Montana Pesticide Education Program

Cecil Tharp, Pesticide Education Specialist

103 Animal Bioscience

Montana State University

Bozeman, MT 59717-3020

Phone: (406) 994-5067