Personal Protective Equipment for Pesticide Applicators

Exposure to pesticides may cause poisoning leading to illness, injury, and in extreme cases, death. Personal protective equipment (PPE) is used to protect the pesticide applicator from poisoning by reducing pesticide exposure. Exposure occurs when pesticides are delivered on or into the body through four routes: skin (dermal), eyes (ocular), lungs (inhalation), and mouth (oral). According to Montana State University Extension Pesticide Education Program (MSU PEP) surveys, less than half of all Montana Farm (Private) Pesticide Applicators always wear required PPE listed on the pesticide product label (Tharp & Bowser, 2022). The result is unnecessary pesticide poisoning. The purpose of this publication is to instruct pesticide applicators to use proper PPE, including how to read the product label, understand chemically-resistant materials and types of PPE, how to clean PPE, and best practices to reduce exposure. By understanding these factors, pesticide applicators can purchase the proper PPE at local chemical distributors, agricultural suppliers, hardware stores, or online safety retailers.

Last Updated: 12/22by By Amy Bowser, MSU Extension Pesticide Education Technician and Cecil Tharp, MSU Extension Pesticide Education Specialist

Read the Pesticide Label

Reading and following the pesticide product label PPE requirements will reduce your pesticide exposure and consequential poisonings (Figure 1). The precautionary statements on the label state the PPE required when mixing, loading, handling, or applying pesticides. Elevated PPE requirements are often required when activities are associated with concentrated active ingredients such as tank mixing. PPE requirements may also vary during the restricted-entry interval (REI), the time after a pesticide application when entry into the treated area is restricted. The REI is stated within the agricultural use or non-agricultural use box, often on the first or second page of the product label.

Personal Protective Equipment

According to many studies, more than 97% of pesticide exposure occurs through the skin, and is therefore an important consideration when selecting proper PPE (National Pesticide Applicator Core Manual, 2014). At minimum for any pesticide application, an applicator needs to wear a long-sleeved shirt, pants, closed-toe shoes, and socks. Coveralls made of cotton or disposable Tyvek® are also acceptable to meet minimum PPE requirements for low-toxicity products with the signal word, CAUTION. More protective PPE is required when applying moderately toxic to highly toxic pesticides with the signal words WARNING, DANGER, or DANGER-POISON.

Many pesticide product labels state the chemically-resistant materials required; however, at times the product label may state only the category of PPE required. Table 1 lists a range of PPE materials from which to choose for each category that may be listed on a pesticide label. For example, the label may say: “Follow the instructions for Category F on an EPA chemical resistance selection chart.” This means you should select PPE made from barrier laminate, butyl rubber, nitrile, or Viton because they are highly resistant to the pesticide.

Applicators must always read and follow the pesticide product label PPE requirements for the precise body protection required. However, some examples are chemical-resistant suits or coveralls, gloves, footwear, apron, and headwear.

Figure 1. A pesticide applicator wearing PPE is protected from pesticide exposure while tank mixing. PPE required differs from pesticide to pesticide. (Adobe Stock)

CHEMICAL RESISTANT SUITS OR COVERALLS

Chemical-resistant coveralls or two-piece suits may be required by the pesticide label when handling moderate to highly toxic pesticides. Chemical resistant means there is no pesticide movement through the fabric during use when used as intended. The degree and duration of protection offered depend on the material, and features of the clothing including taped seams, covered zippers, hoods, and elasticized sleeves. Chemical-resistant suits are composed of or coated with butyl rubber, neoprene, PVC, polyethylene, Viton® or other material. Disposable coveralls such as regular Tyvek®, Comfort Guard, Kappler ProVent®, and KleenGuard™ are breathable suits that offer some protection from mists, but they are not recommended for chemical protection (Whitford et al., 2003). Some common brand names offering chemical resistance are DuPont, Guardian, Lakeland, and Tingley. The product label will define the type of material and suit required. It is very important to follow these requirements, as not all materials work for all pesticides.

If there is an attached hood not being used, tuck it inside the neckline so it will not collect pesticides. Inspect your PPE for wear and material degradation prior to use as these areas may allow pesticides to contact your skin. Do not use if you find holes, rips, tears, or material degradation. Discoloration is often a sign of material degradation and serves as a warning the PPE should be replaced.

GLOVES

According to surveys, more than half (55%) of all Montana Farm (Private) Pesticide Applicators have removed label- required gloves when applying pesticides (Tharp & Bowser, 2022). Gloves protect the skin on your hands from pesticide exposure. The pesticide product label will list the specific material required for the product you are using. When gloves are required, wear unlined, elbow-length chemical-resistant gloves. While thickness may not be listed on the label, 14 mils is the typical thickness needed for chemical resistance. Some applicators elect to wear thinner-disposable chemically resistant gloves under the 14 mil gloves as an additional layer of protection.

Check closely for holes by filling the gloves with air or clean water and gently squeezing. Throw out the gloves if any holes or discoloration appear. In the case of where your hands are reaching up (such as changing nozzles), turn glove cuffs up to form a cup to trap any liquid that runs down the arm or ensure gloves cover the sleeves of the chemically-resistant coveralls and are not inserted within the sleeve.

Do not use fingerless gloves, latex gloves, lined gloves, leather gloves, or cotton gloves. An exception is fumigating with a product such as aluminum phosphide where leather or cotton gloves are required.

Table 1. EPA Chemical Resistance Category Selection Chart

|

Category

|

Barrier Laminate

|

Butyl rubber

≥ 14 mils

|

Nitrile rubber

≥ 14 mils

|

Neoprene rubber

≥ 14 mils

|

Natural rubber

≥ 14 mils

|

Polyethylene

|

Polyvinyl chloride (PVC)

≥ 14 mils

|

Viton

≥ 14 mils

|

| A | High | High | High | High | High | High | High | High |

| B | High | High | Slight | Slight | None | Slight | Slight | Slight |

| C | High | High | High | High | Moderate | Moderate | High | High |

| D | High | High | Moderate | Moderate | None | None | None | Slight |

| E | High | Slight | High | High | Slight | None | Moderate | High |

| F | High | High | High | Moderate | Slight | None | Slight | High |

| G | High | High | Slight | Slight | None | None | None | High |

| H | High | High | Slight | Slight | None | None | None | High |

FOOTWEAR

When applying pesticides, it is important to protect your feet especially when walking through treated areas. Do not wear canvas or leather boots as pesticides will absorb into the material and they are difficult to clean. Wear unlined chemical- resistant boots which cover your ankles when handling or applying pesticides. Materials may vary; however, rubber boots purchased from local agricultural suppliers will protect against most pesticides. Pant legs should be worn over boots to prevent the pesticide from draining into the boot. An alternative to wearing chemical-resistant boots is to wear chemical-resistant over-boots with washable shoes. Wash socks and canvas sneakers worn under chemical-resistant boots just like you would pesticide-contaminated clothing.

HEADWEAR

An applicator’s head and neck should also be protected. This is most important in situations where exposure from overhead dusts or sprays is possible, such as hand-spraying uphill or when flagging for aerial applications. PPE with built-in hoods, wide-brimmed chemical-resistant hats, and washable hard hats (with no absorbing liner) are good options. Do not use cotton or felt hats as they will absorb pesticides. Any hat used should be washed properly after the application.

APRON

The pesticide product label may require a chemically-resistant apron when repairing or cleaning spray equipment and when mixing or loading a spray tank. Aprons offer additional protection against spills and splashes of liquid formulations, but they are also useful when handling dry formulations such as wettable powders. Read the pesticide product label for best materials; however, nitrile, butyl, and neoprene often offer the best overall protection.

EYE PROTECTION

Eye protection should be worn when required by the pesticide product label or when a chemical could possibly contact the eyes, such as splashing when mixing and loading a spray tank. Safety glasses with brow and side shields are acceptable for low-exposure situations (Figure 2). In high-exposure situations when both face and eye protection are needed, wear a face shield over goggles or a full-face respirator. Never wear prescription eyeglasses or sunglasses as a form of eye protection. Do not wear contacts as they facilitate absorption of chemicals into the eye.

Figure 2. Safety glasses with side shields (Adobe Stock).

RESPIRATORS

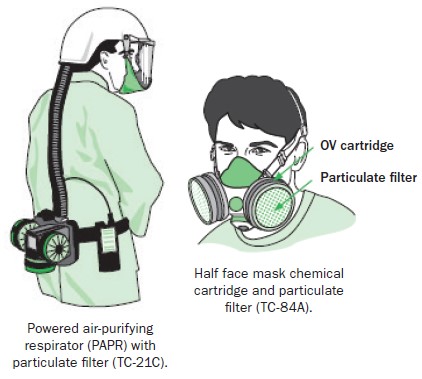

Respirators protect you from inhaling toxic chemicals by either supplying clean air or filtering out contaminants in surrounding air. The pesticide product label will tell if a respirator is required and what type. Respirators are regulated by the National Institute for Occupational Safety and Health (NIOSH), which assigns approval numbers to different types of respirators. This number tells which type of respirator you must wear while applying a specific pesticide. A comprehensive list of NIOSH approval numbers and descriptions is available in Table 2.

Atmosphere-supplying respirators where other types of respirators will not provide enough protection or there is low oxygen. There are two types of air-supplying respirators: self-contained breathing apparatus (SCBA) with a NIOSH approval #TC-13F and supplied-air respirators (SAR) with NIOSH approval #TC-19C. A SCBA supplies air from a tank to a full-face mask whereas a SAR is connected to an outside air source through a hose. With the use of some fumigants, SCBA or SAR is required if an applicator must enter a structure at extremely high fumigant concentrations.

Air-purifying respirators (APR) remove contaminants from the surrounding air through a filter, cartridge, or canister. The NIOSH approval number for this type of respirator is most commonly TC-84A and TC-21C (Figure 3). There are several criteria to be considered when using an air-purifying respirator including the filter efficiency, oil resistance, the type of cartridge required and powered or non-powered. The filter efficiency will be listed as a percentage of how much of a contaminant is removed: 95%, 99% or 100% efficiency. A respirator will also list its oil degradation resistance as N (not oil resistant), R (oil resistant up to eight hours) or P (oilproof). An example is an N95 dust mask is 95% efficient at removing particulates and is not oil-resistant.

Table 2. NIOSH Designations for Respirators

| NIOSH Approval Number | Type |

TC-84A |

|

| TC-21C |

|

TC-23C |

|

TC-14G |

|

TC-13F |

|

| TC-19C |

|

|

Definitions: APR – Air-purifying respirator N – Not oil resistant

PAPR – Powered air-purifying respirator R – Oil resistant up to 8 hours

SCBA – Self-contained breathing apparatus P – Oilproof

SAR – Supplied-air respirator

|

Air-purifying respirators may use cartridges specific to a contaminant to remove gases and vapors, however they do not remove particulates. The most common pesticide cartridge type is organic vapor removing. You must use the type of cartridge listed on the pesticide product label. Chemical cartridges are 100% efficient at removing contaminants until there is breakthrough. If you notice any smells or irritation while using this type of respirator, immediately move to fresh air and replace the cartridge. Cartridges have expiration dates, as well as maximum hours of use. When either of these is exceeded, you need to replace the cartridge. Cartridges can be stored in sealed containers to extend their life after opening; however, follow all manufacturer instructions on disposing, cleaning, or storing. It is common in Montana for pesticide applicators to use APR’s with a combination filter and a cartridge that simultaneously filters particulates and vapors for a few highly-toxic pesticides.

Figure 3. Examples of TC-21C and TC-84A respirators (EPA, 2014).

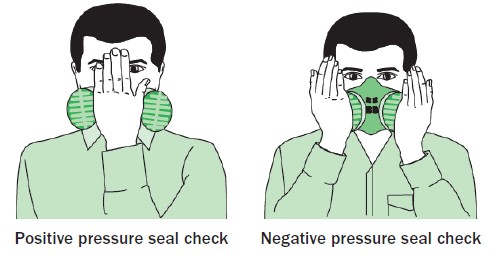

Seal Check

A seal check should be completed every time you wear a respirator. A seal check makes sure the face piece seals properly on your face without allowing airflow around the face mask. To perform a positive-pressure seal check, cover the exhalation port with your palm and exhale. To perform a negative-pressure seal check, cover the inhalation ports on either side of the mask with your hands and inhale (Figure 4). If you feel or hear any air moving into the mask around the seal of the mask, the seal check failed and you need to inspect or adjust your face mask. Prior to entering an area with contaminated air, you should pass either the positive-pressure or negative-pressure seal checks, preferably both. A respirator may fail a seal check due to facial hair, changes in face shape, loose straps, or degradation of the face mask. An example of a seal test can be viewed online at https://pesticides.montana.edu/reference/index.html.

Figure 4. Respirator seal check (EPA, 2014).

Requirements of Using Respirators

When using an agricultural pesticide requiring the use of a respirator you must do the following:

- Get a medical evaluation from a medical professional certifying your ability to safely wear a respirator while applying pesticides. Wearing a respirator can be stressful on the body and can exacerbate heart and lung conditions.

- Fit test to ensure your respirator is the right size and shape for your face. Do fit testing annually or when your face shape and size change (i.e., weight loss or gain).

- Train workers and handlers annually on how to properly use a respirator.

- Maintain records of the above three tasks.

For more information on pesticide medical evaluations, fit testing, and annual training, see the WPS respirator requirements at https://pesticides.montana.edu/wps/

respirators.html.

Cleaning and Maintaining PPE

Reusable PPE should be washed with heavy liquid detergent, such as dish soap mixed with water, in the field after applying pesticides. First, wash your chemical-resistant outer layer with soap and water prior to carefully removing. Remove additional PPE by washing gloved hands then removing the item, washing the item, followed by washing gloved hands again. Repeat for each PPE item, removing your gloves last. When removing respirators, dispose of components such as cartridges, canisters, and filters prior to washing the respirator housing. If a canister or cartridge is not expired, clean surfaces with a paper towel soaked in heavy detergent and water prior to storing in an airtight container.

Washable work clothing and woven PPE which has encountered pesticides should be washed in the washing machine using hot water and heavy detergent with an extra rinse cycle. Follow up the load with an empty wash cycle to remove any remaining residue from the washer. Always wash pesticide-contaminated clothing separately from family clothing and never use bleach when cleaning pesticide-contaminated clothing. Avoid using the dryer as it is difficult to remove pesticide residue.

Hang your PPE and work clothes in the sun after washing to break down any remaining residue.

A Note on Fumigant PPE

While many commonly used pesticides in Montana have similar PPE requirements, the exception is fumigation using aluminum or magnesium phosphide. These chemical-active ingredients are often used in vertebrate pest and structural pest control applications. When using this type of pesticide, you need to wear cotton or leather gloves and breathable clothing including cotton shirts and pants. A full-face gas mask with a phosphine gas canister is also required. Additionally, monitoring equipment is important to observe gas levels nearby. For more information, please view the MontGuide titled Structural and Rodent Fumigation in Montana Agricultural Systems (MT201904AG), available at the MSU Extension Store (https://store.msuextension.org). Always read and follow the pesticide label and applicator manual when fumigating.

Best Practices to Reduce Exposure

- Read the pesticide product label prior to every application and follow the PPE requirements.

- At minimum, wear a long-sleeved shirt, long pants, socks, and closed-toe shoes when applying pesticides.

- Plan applications in advance to ensure proper PPE is available.

- Clean PPE after every use with heavy detergent and water.

- Inspect and maintain PPE before and after use. Do not use degraded PPE.

- Keep track of respirator cartridge expiration dates and hours used.

- Wash pesticide work clothing separately from family clothing using hot water and detergent followed by an extra rinse cycle.

- Always wash hands before eating, using the bathroom, smoking, or answering a phone.

- Always store pesticides in their original pesticide container to eliminate accidental ingestion or accidents.

- Never spray when wind conditions are creating significant drift.

References

Funding and More Information

This publication was supported through funds from the Extension Foundation. Additional MSU Pesticide Education resources are available online at www.pesticides.montana.edu under “Publications and Resources.” You may also contact your local MSU Extension agent or the MSU Extension Pesticide Education Program: